Fluid Management

Key Benefits and Advantages of Fluid Management:

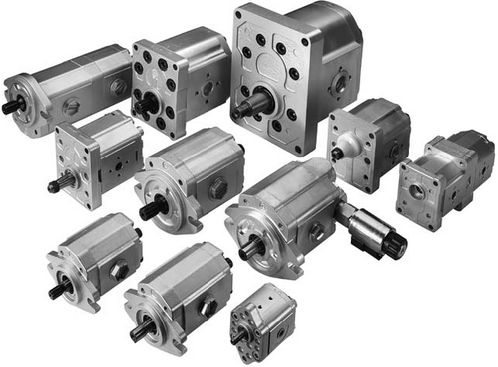

- Improved Equipment Longevity and Reliability: Ensures machinery operates efficiently with less wear and tear through regular monitoring and maintenance, extending the life of critical components and preventing failures caused by contamination or improper fluid levels, thereby minimizing unexpected breakdowns and keeping machinery running smoothly.

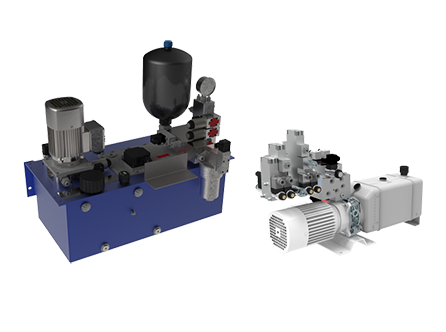

- Enhanced Efficiency and Cost Reduction: Optimizes fluid use to reduce wastage and provides consistent, reliable energy, leading to machinery operating at optimal performance while reducing energy consumption. This lowers maintenance costs by preventing damage, reduces the need for frequent fluid replacements, and cuts down on waste disposal costs.

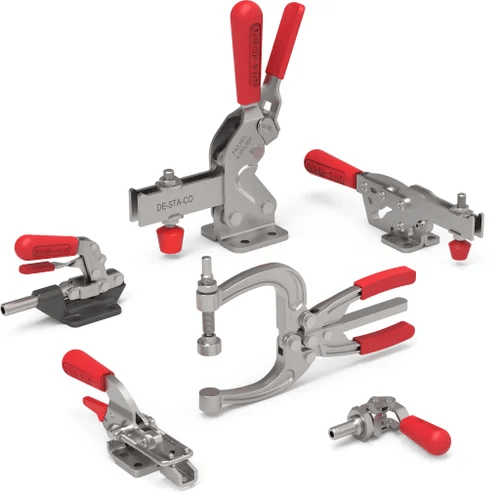

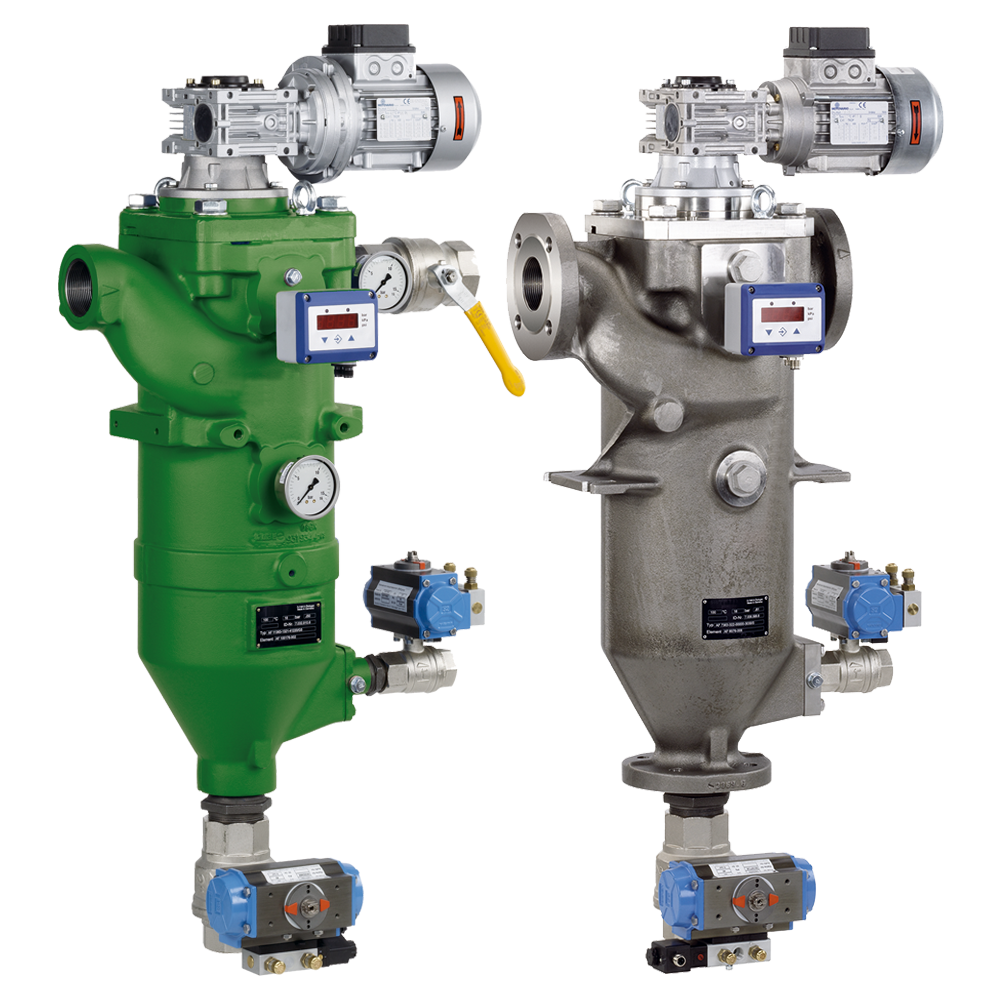

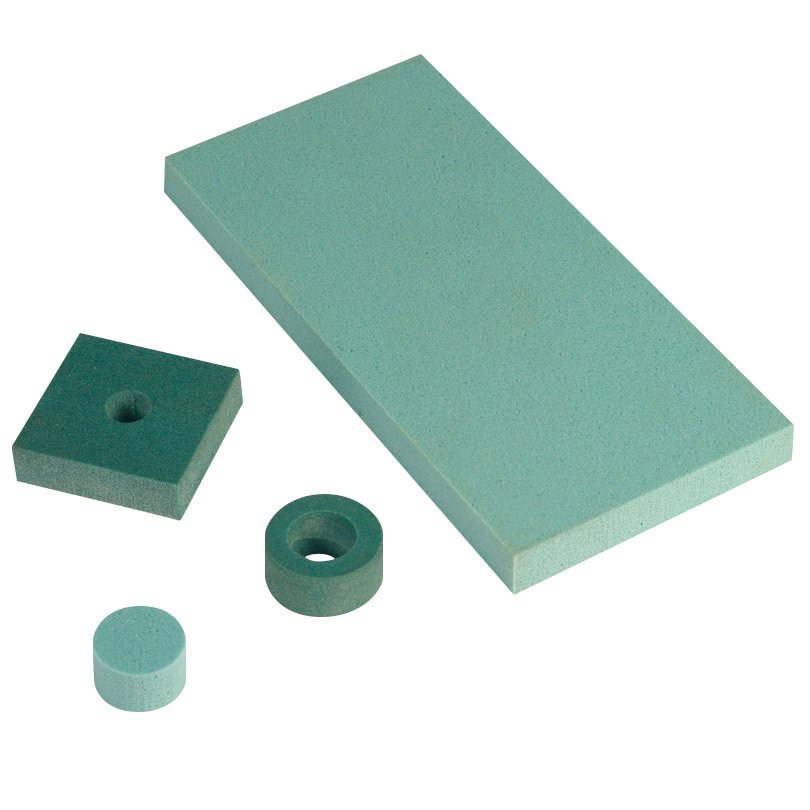

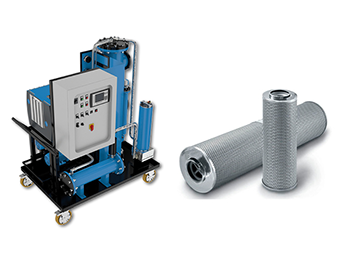

- Prevention of Contamination: Includes strategies like filtration and proper handling to safeguard equipment and enhance performance by preventing contamination, a common cause of system failures.

- Environmental Responsibility: Contributes to more sustainable and environmentally friendly operations by ensuring optimal fluid usage, reducing waste, and helping businesses comply with regulations on fluid disposal and waste management, thus preventing fines and reducing ecological impact.

- Optimized Fluid Usage and Resource Conservation: Ensures the right amount of fluid is used for each application, reducing wastage and helping to conserve resources, which is both cost-effective and environmentally friendly.

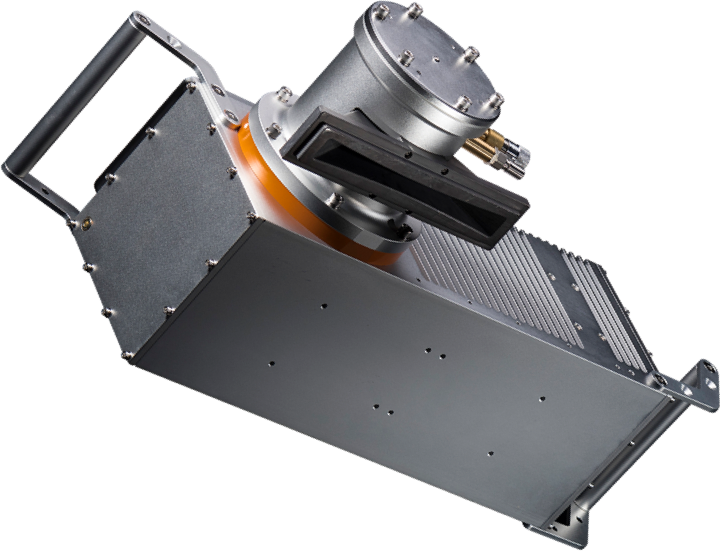

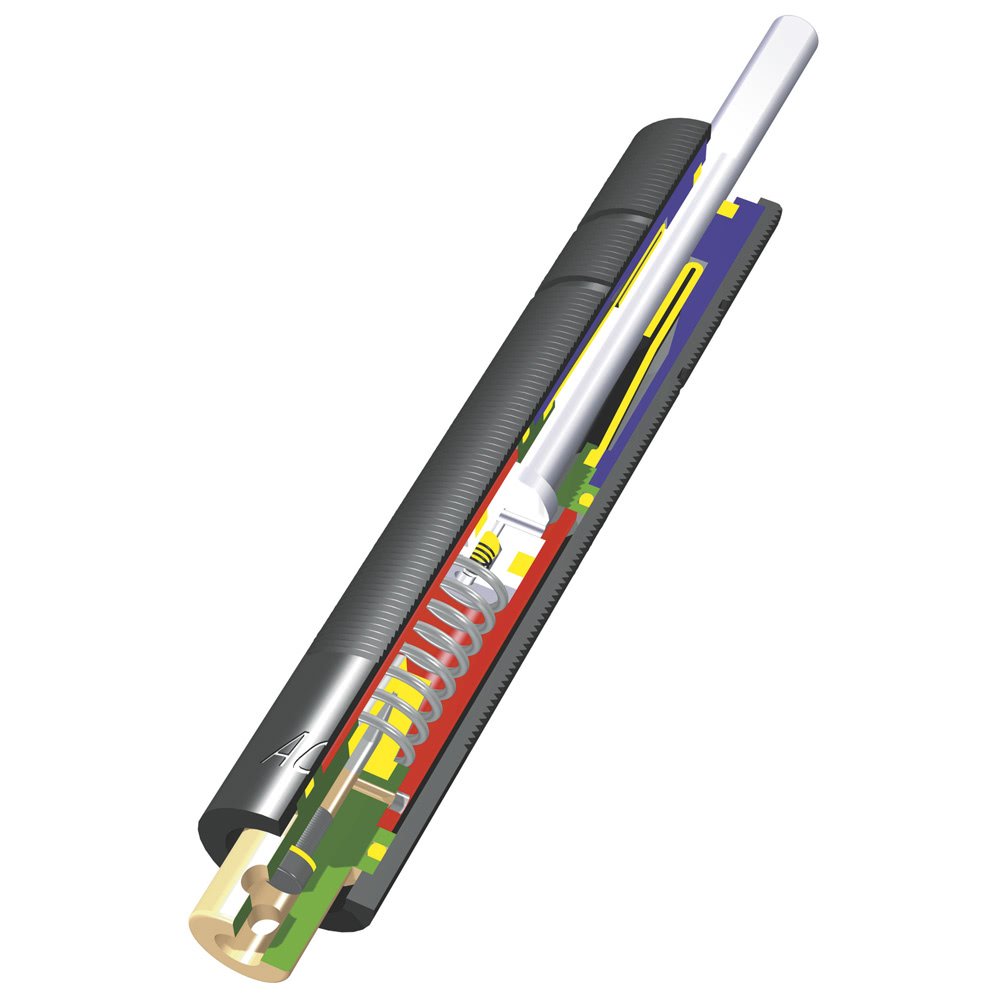

- Automated Monitoring and Control: Advanced fluid management solutions often feature automated systems for fluid level monitoring, filtering, and replenishment, reducing human error and ensuring fluid quality is maintained within optimal ranges.

- Enhanced Safety: Proper management of fluids helps ensure safe operation by preventing issues like overheating, excessive pressure buildup, or contamination that could lead to unsafe operating conditions or even catastrophic failures.

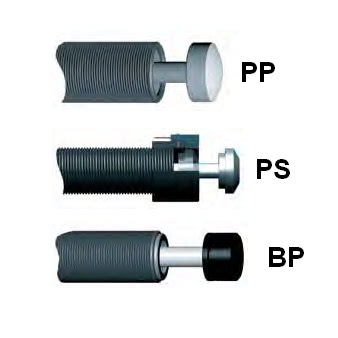

- Flexibility for Different Fluids: Systems can be adapted for use with a wide variety of fluids, such as hydraulic oils, lubricants, coolants, and even specialized fluids like food-grade lubricants, making fluid management systems suitable for a broad range of industries.