Autonics Stepper Motors

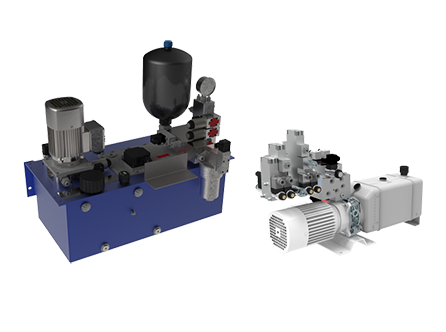

Autonics stepper motors are precision-engineered electromechanical devices designed to convert electrical pulses into precise mechanical motion. These motors offer accurate positioning and control capabilities, making them ideal for applications that require precise and repeatable movement.

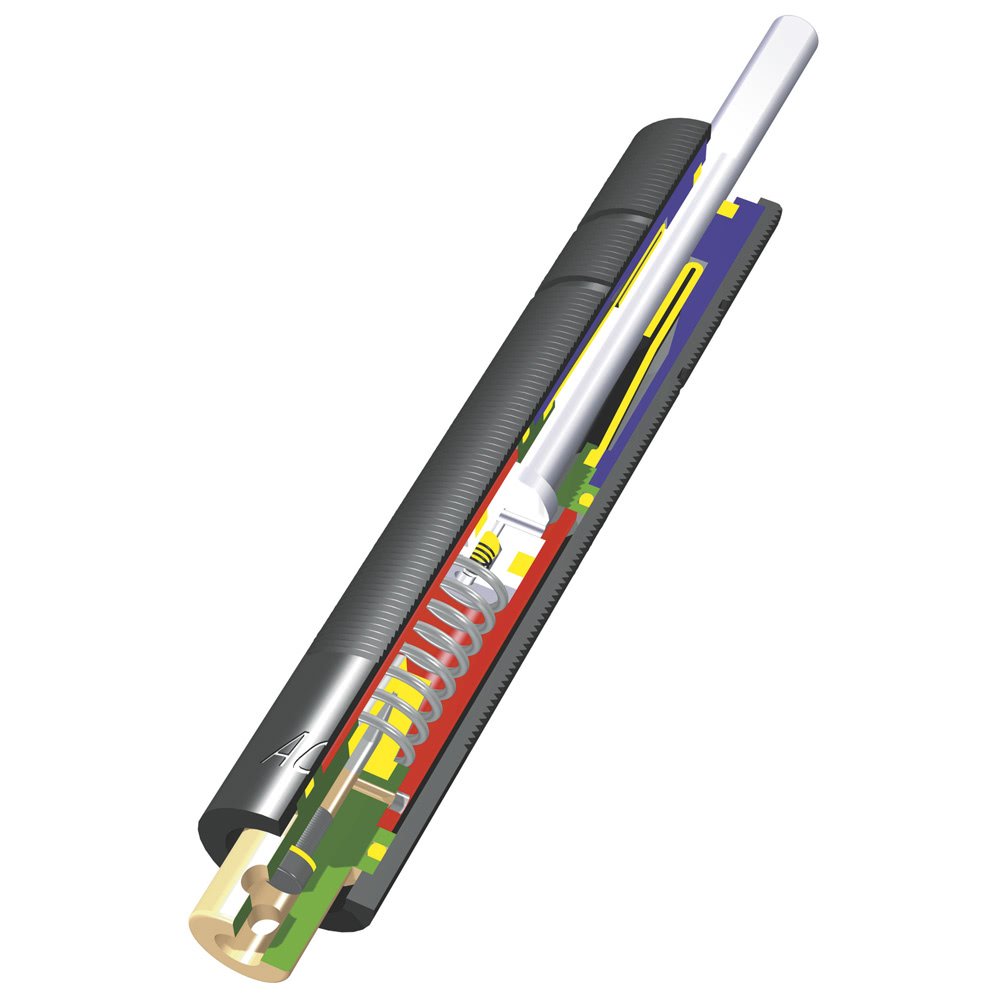

Autonics stepper motors consist of a rotor and stator arrangement. The rotor is a permanent magnet, while the stator contains multiple sets of electromagnetic coils. When electrical pulses are applied to the coils in a specific sequence, a magnetic field is generated, causing the rotor to move in a step-wise manner. The number of steps per revolution determines the motor's resolution.

One of the key advantages of Autonics stepper motors is their ability to achieve precise positioning. By controlling the number of pulses applied to the motor, it can be accurately moved to a desired position or angle. This level of control makes them well-suited for applications such as robotics, CNC machines, 3D printers, and automated equipment.

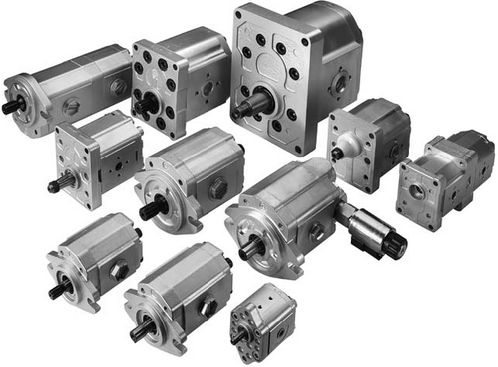

Autonics stepper motors offer various features and options to meet specific application requirements. These may include different step angles, torque ratings, holding torque capabilities, and shaft configurations. Some models may also incorporate additional features like built-in encoders for improved position feedback.

Autonics stepper motors are known for their reliability, durability, and long lifespan. They are designed to withstand demanding operating conditions and provide consistent performance over extended periods. Additionally, they are generally easy to integrate and control, thanks to their compatibility with standard motor drive systems and interfaces.

In summary, Autonics stepper motors are high-precision electromechanical devices that convert electrical pulses into precise mechanical motion. With their accurate positioning capabilities, these motors are widely used in various applications where precise and repeatable movement is required. Autonics stepper motors are known for their reliability, durability, and compatibility, making them a popular choice for automation and motion control systems.

-

Robotics: Autonics stepper motors are widely used in robotic systems for precise positioning and motion control. They provide accurate and repeatable movement, making them ideal for tasks such as robotic arm control, pick-and-place operations, and automated assembly lines.

-

CNC Machines: Computer Numerical Control (CNC) machines rely on Autonics stepper motors for precise and controlled movement of machine tools. These motors ensure accurate positioning of the cutting or milling tools, enabling high-precision machining operations in industries such as manufacturing, woodworking, and metalworking.

-

3D Printers: Autonics stepper motors are integral components in 3D printers, responsible for precise control of the printer head movement along the X, Y, and Z axes. The motors enable accurate layer-by-layer printing, resulting in high-quality and intricate 3D models.

-

Textile Machinery: Autonics stepper motors play a crucial role in textile machinery, controlling the movement of rollers, spinning wheels, and other components. Their precise positioning and speed control contribute to efficient weaving, knitting, and spinning operations in the textile industry.

-

Medical Equipment: Autonics stepper motors are used in various medical equipment, including laboratory automation systems, medical pumps, and imaging devices. These motors provide precise and controlled movements required for sample handling, fluid dispensing, and positioning of medical instruments.

-

Packaging Machinery: Autonics stepper motors are employed in packaging machines to control the movement of conveyor belts, rollers, and packaging elements. Their accuracy and repeatability ensure precise packaging, labeling, and sealing processes in industries such as food and beverage, pharmaceuticals, and logistics.

-

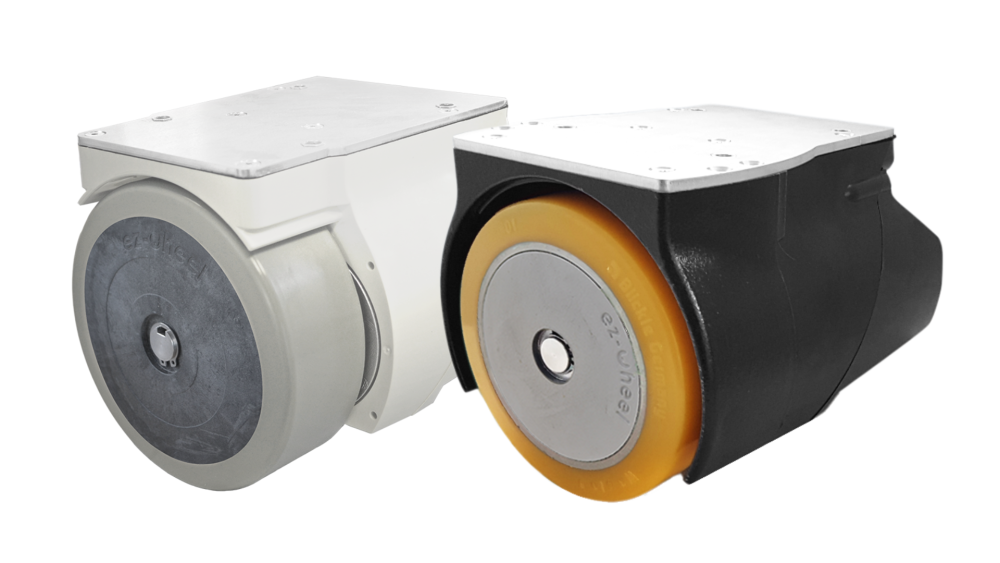

Automated Guided Vehicles (AGVs): AGVs are used for material handling and logistics in warehouses and manufacturing facilities. Autonics stepper motors enable precise navigation and movement control of AGVs, allowing them to follow predefined paths, avoid obstacles, and accurately position themselves for loading and unloading operations.

-

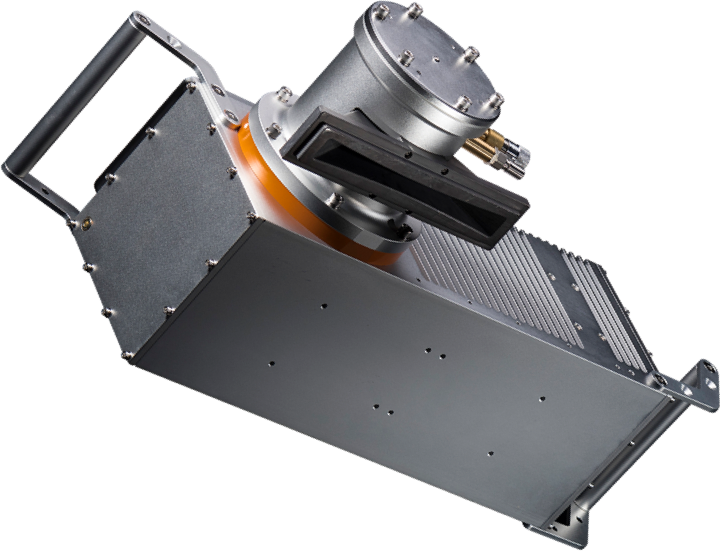

Semiconductor Manufacturing: Autonics stepper motors are utilized in semiconductor manufacturing equipment for wafer handling, precision positioning, and alignment tasks. These motors ensure accurate movement during the fabrication processes, contributing to the production of high-quality integrated circuits.

-

Precise Positioning: Autonics stepper motors offer high-precision positioning capabilities, allowing for accurate and reliable movement control. They can move in discrete steps, providing precise control over rotational or linear motion.

-

Steady Torque: These motors deliver consistent torque output across a wide range of speeds, ensuring stable and reliable performance. This characteristic makes them suitable for applications that require controlled and predictable movement.

-

Excellent Response and Acceleration: Autonics stepper motors exhibit quick response times and high acceleration rates, enabling rapid and efficient motion control. This characteristic is particularly valuable in applications that demand fast and precise positioning.

-

Bipolar and Unipolar Configurations: Autonics stepper motors are available in both bipolar and unipolar configurations, providing flexibility to suit different system requirements. Bipolar motors offer higher torque and are commonly used in demanding applications, while unipolar motors are simpler to drive and operate.

-

Compact and Space-Efficient Design: Autonics stepper motors are designed with compact dimensions, allowing for easy integration into space-constrained environments or equipment. Their compact size makes them suitable for various applications where size and weight limitations exist.

-

High Reliability and Durability: Autonics stepper motors are built to withstand rigorous operating conditions. They are engineered with robust construction, durable materials, and precise manufacturing processes, ensuring long-term reliability and extended service life.

-

Low Energy Consumption: Autonics stepper motors are energy-efficient devices, consuming minimal power during operation. This characteristic contributes to cost savings and enables their use in applications where power consumption needs to be minimized.

-

Compatibility with Control Systems: Autonics stepper motors can be easily interfaced with various control systems and controllers, facilitating seamless integration into automation and motion control systems. They are compatible with a range of communication protocols and can be operated through standard interfaces.

-

Versatile Application Range: Autonics stepper motors find applications in diverse industries, including robotics, CNC machines, 3D printers, medical equipment, laboratory automation, and more. Their versatility allows them to adapt to different motion control requirements across various sectors.

Stepper motors are electromechanical devices widely used in various applications that require precise and controlled rotational movement. They are known for their ability to divide a full rotation into a series of discrete steps, allowing for accurate positioning and control.

Autonics stepper motors are likely to have the following features and specifications:

-

Step Angle: Stepper motors rotate in fixed increments known as step angles. Autonics stepper motors may have different step angles such as 1.8 degrees (common for standard stepper motors) or 0.9 degrees (known as a "half-step" motor, offering finer resolution).

-

Holding Torque: This refers to the maximum torque the stepper motor can generate when holding its position without rotation. Autonics stepper motors may have varying holding torque values depending on the model.

-

Motor Size and Frame: Stepper motors come in various sizes and frame types. Autonics stepper motors are likely to be available in different frame sizes, such as NEMA (National Electrical Manufacturers Association) standard sizes like NEMA 17, NEMA 23, or NEMA 34, indicating the dimensions and mounting configuration.

-

Voltage and Current Ratings: Autonics stepper motors will have specific voltage and current requirements for operation. These values indicate the electrical power needed to drive the motor and may vary depending on the specific model.

-

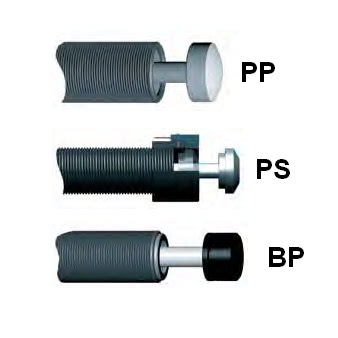

Shaft Configuration: The stepper motor's shaft configuration determines how it connects to the driven system. Autonics stepper motors may offer various shaft types, such as single or double shafts, with different lengths and diameters.

-

Connection Type: Autonics stepper motors might have specific connection interfaces, such as wire leads or connectors, for convenient electrical connections.