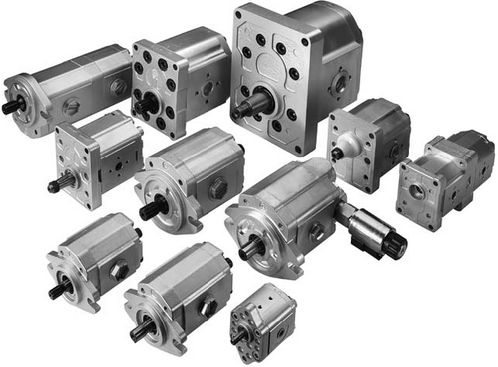

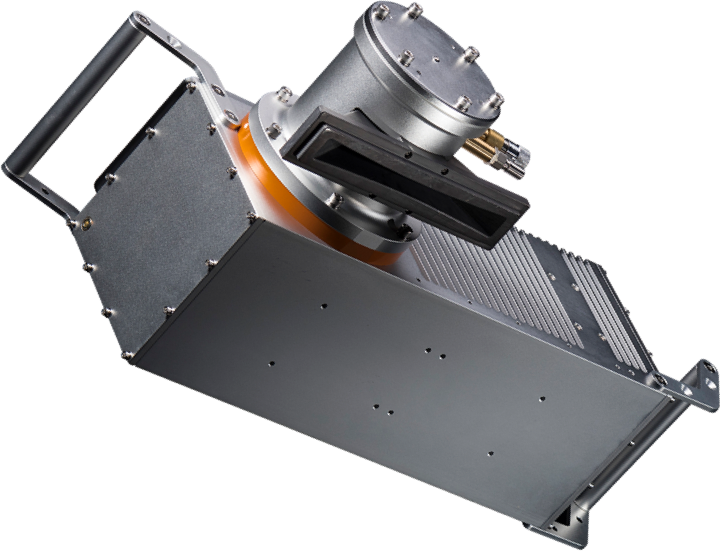

Metering pumps

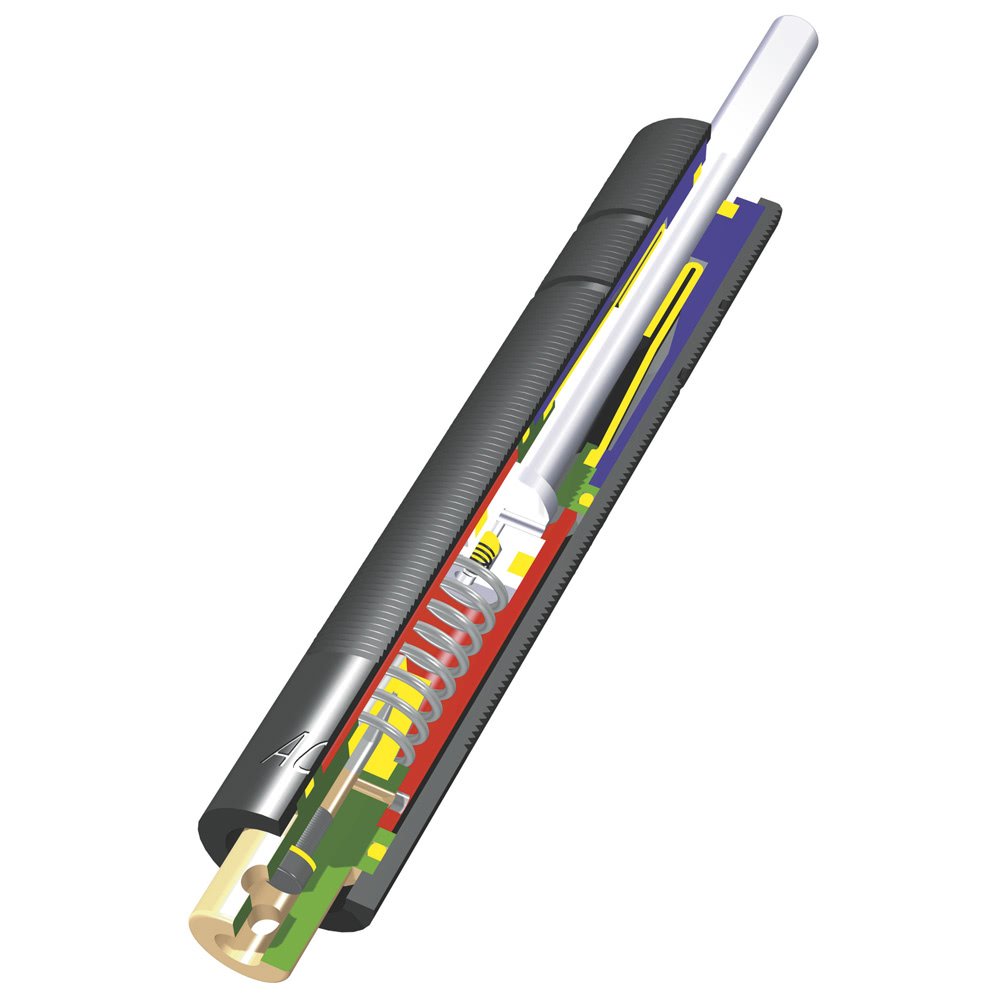

Dosing pump is designed for precisely delivering a set amount of fluid (often chemicals or additives) at a specific flow rate, usually at low pressures

Characteristics:

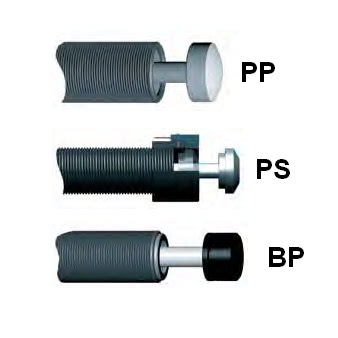

- Designed to precisely deliver a controlled volume of fluid (liquids, chemicals, or other additives) into a system.

- Fluid Type: Often used for dispensing chemicals, water treatment fluids, pharmaceuticals, food additives, or cleaning agents.

- Pressure Range: Operates at low to moderate pressures compared to hydraulic pumps (usually under 200 PSI).

- Application: Common in water treatment, chemical dosing, pharmaceutical manufacturing, and food processing industries.

- Flow Rate: Designed for precise control, metering pumps deliver a small and consistent volume of fluid, often in milliliters or liters per hour.

Advantages:

- Precise flow control ensures accurate dosing of chemicals or fluids.

- Adjustable flow rates for varying application needs.

- Ideal for applications where precise fluid injection or dosing is crucial, such as in water treatment, chemical manufacturing, and pharmaceutical production.