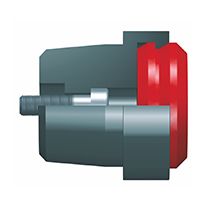

MC64 series

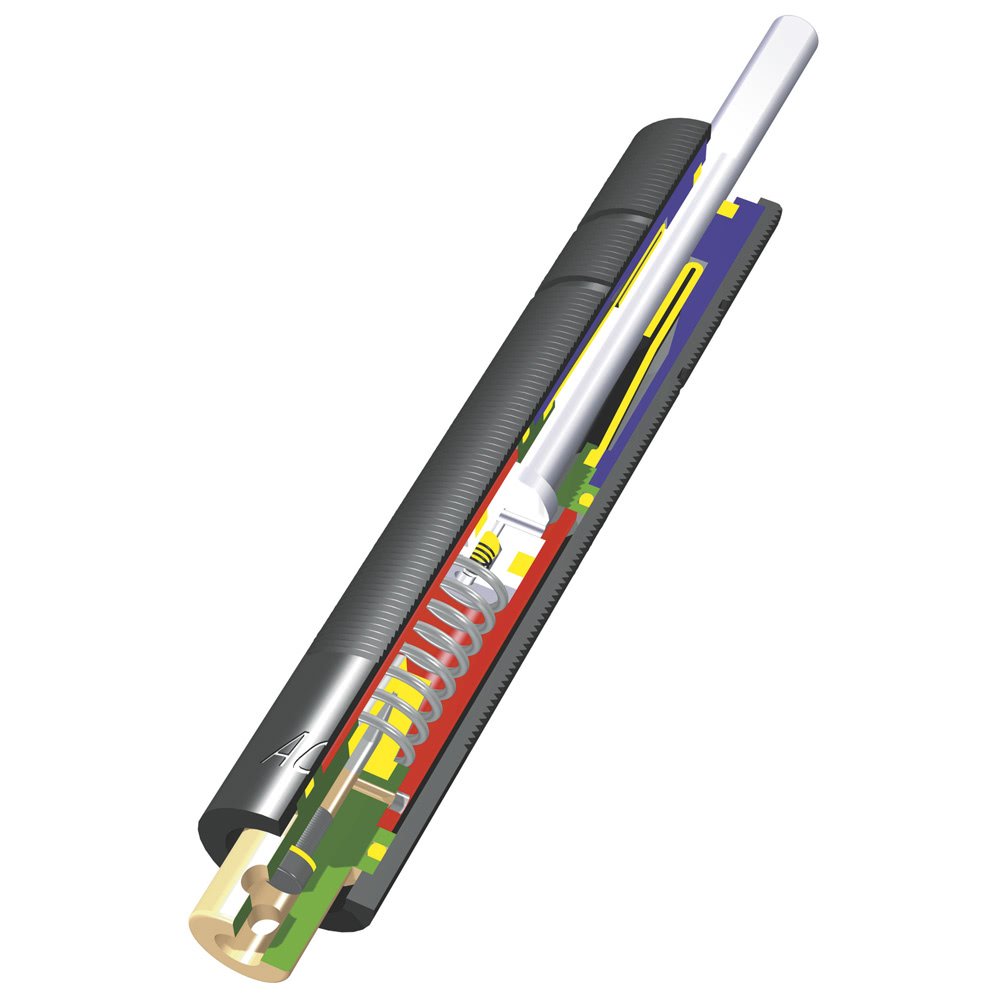

The latest shock absorber technology: The combination of the latest sealing technology, annealed guide bearing and integrated fixed thrust bearing explains the success of this range of ACE MC64 MAGNUM self-compensating shock absorbers. With them, users benefit from products with a longer service life, even in the harshest environments. The continuous external thread and numerous accessories are further reasons for the success of the MC6450, MC64100, and MC64150 products. High energy absorption in a compact design and damping over a wide spectrum provide enormous advantages in practice. In addition to being associated with generally more compact constructions, these small dampers are very powerful and allow the best possible use of the machine's full performance. These self-compensating industrial shock absorbers are used in all areas of mechanical engineering, especially in automation and gantry applications.

Capacity: 170 Nm/Cycle to 5,650 Nm/Cycle

Impact speed: 0.15 m/s to 5 m/s. Other speeds on request.

Operating temperature: -12 °C to +66 °C. Please consult us for different temperatures.

Mounting: optional

Fixed stop: integrated

Materials: Outer body: hardened steel; piston rod: hard chromed steel; stop: hardened and corrosion-resistant steel; return spring: zinc-plated steel or plastic-coated steel; accessories: phosphate or hardened steel

Damping fluid : Automatic Transmission Fluid (ATF)

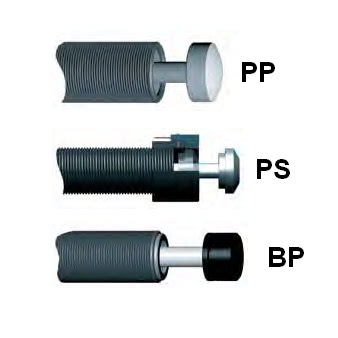

Note: It is possible to reduce the noise from 3 dB to 7 dB by using the special bumper (PP). For emergency stop applications and for continuous operation (with additional cooling) it is sometimes possible to exceed the specified maximum capacities. In this case, please consult us.

Safety instructions: External materials from the immediate environment can attack the sealing components and shorten the service life. Please contact us for proposals for suitable solutions. Do not paint the shock absorbers due to heat emission.

Special oils, nickel plating, increased corrosion protection, integration in pneumatic cylinders or other special options are available on request.

linear carriages, rotation units, turntables, gates, machines and systems, machine tools, machining centres, Z-axes, bumper plates, handling modules

Increases production rate

Prolongs machine life

Reduces construction costs

Reduces maintenance and noise

-

View accessories

-

View accessories

-

View accessories

-

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

-

View accessories

-

View accessories

-

-

View accessories