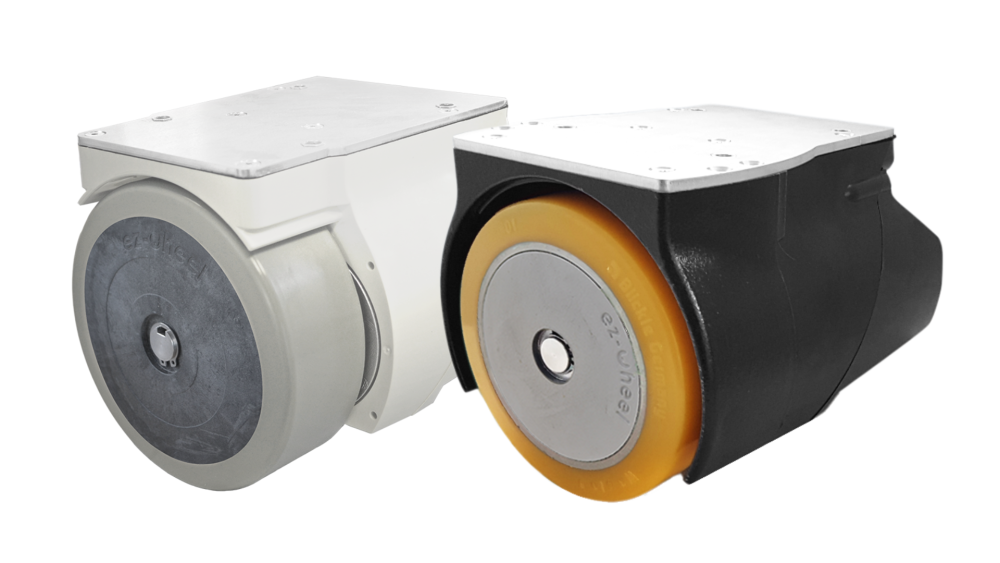

MC150 to 600 series

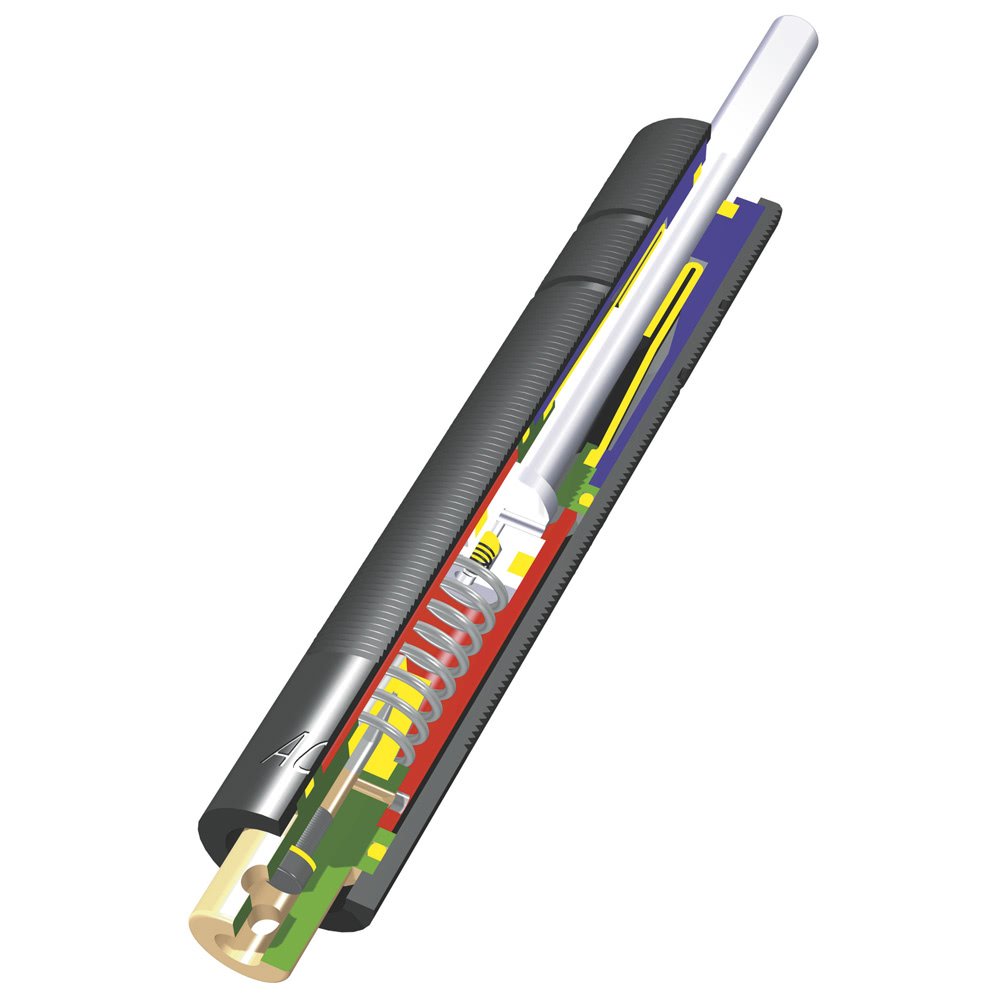

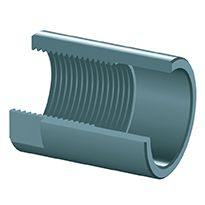

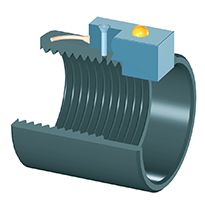

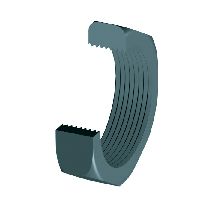

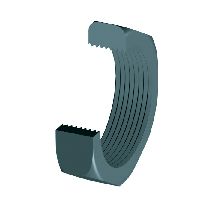

Proven and durable: With a hermetically sealed rolling diaphragm in each damper, ACE's MC150, MC225 and MC600 product family offers exceptional durability for use up to 25 million cycles. The rolling diaphragm technology perfected by ACE guarantees complete separation of the damping fluid from the surrounding air, allowing it to be installed directly in a pressure chamber, for example as a limit stop in pneumatic cylinders up to approx. 7 bar.

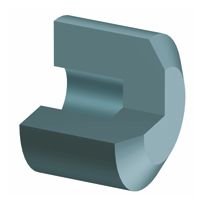

The rolling diaphragm also promotes very low restoring forces for these maintenance-free, ready-to-install dampers. Progressive capacities with a high effective mass potential, combined with an integrated fixed end stop, make these miniature shock absorbers a most advantageous solution. In addition, an adapter for radial forces allows angles of impact of up to 25° to be accepted.

Miniature shock absorbers are universally mountable even in a cylinder and are also available in stainless steel. They are often used in machine and plant construction and in a multitude of other applications.

Capacity: 20 Nm/Cycle to 136 Nm/Cycle

Impact speed: 0.06 m/s to 6 m/s (other speeds on request)

Operating temperature : 0 °C to 66 °C

Mounting: your choice

Fixed stop: integrated

Materials: Outer body, accessories: Corrosion-resistant coated steel; guide bush: plastic; piston rod: hardened stainless steel (1.4125, AISI 440C); rolling diaphragm : EPDM

Damping fluid: oil, temperature stable

Safety instructions: External materials from the immediate environment can attack the rolling seal and shorten its service life. Please contact us for proposals of suitable solutions.

On request: Increased corrosion protection. Special threads or other special executions.

Linear slides, pneumatic cylinders, rotation units, handling modules, machines and plants, manufacturing and machining centres, measuring tables, machine tools, locking systems

Increases production rate

Prolongs machine life

Reduces construction costs

Reduces maintenance and noise

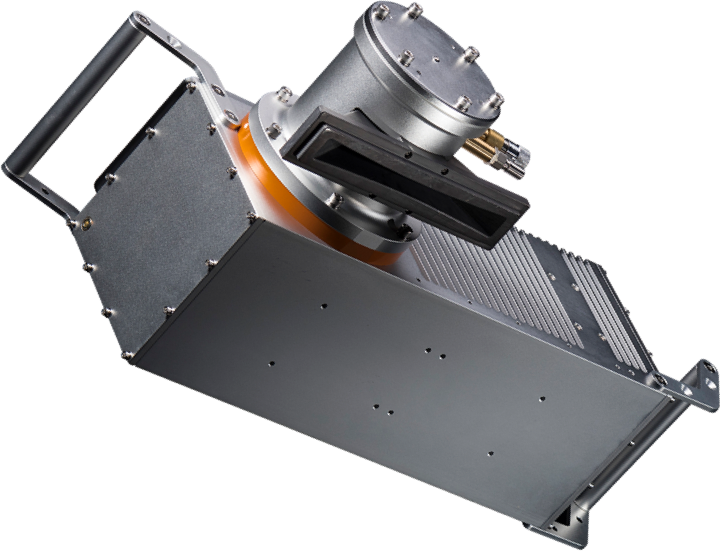

ACE Industrial Dampers are professional linear deceleration devices for today's sophisticated automation systems.

High capacity and reinforced construction ensure a long service life under severe conditions. A wide range of sizes is available for masses from a few grams to several hundred tons.

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories