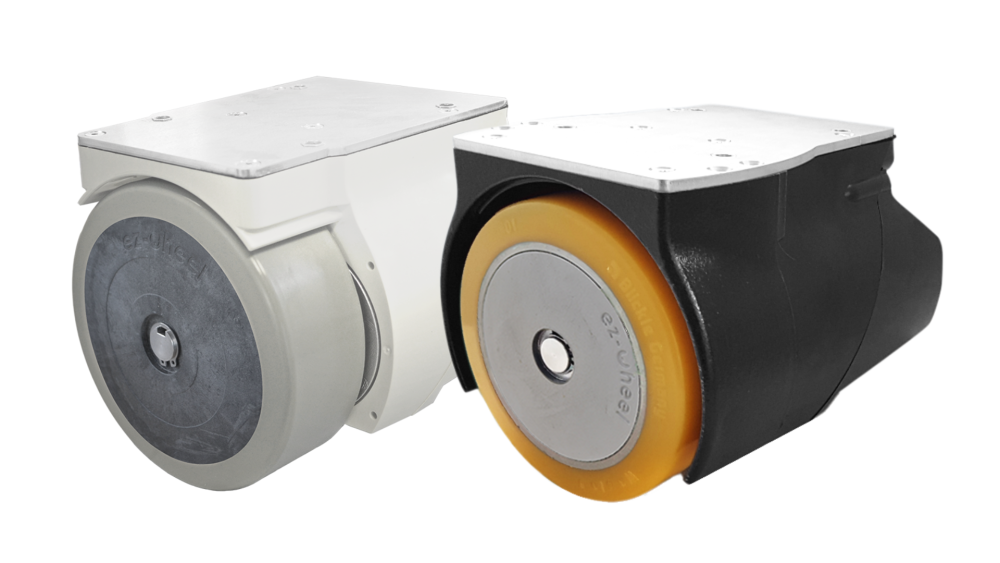

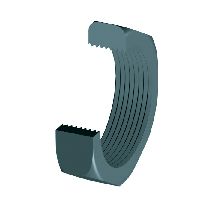

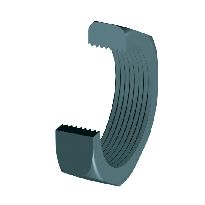

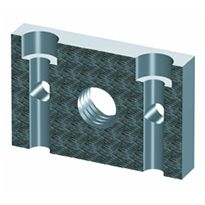

PMCN150 to 600 series

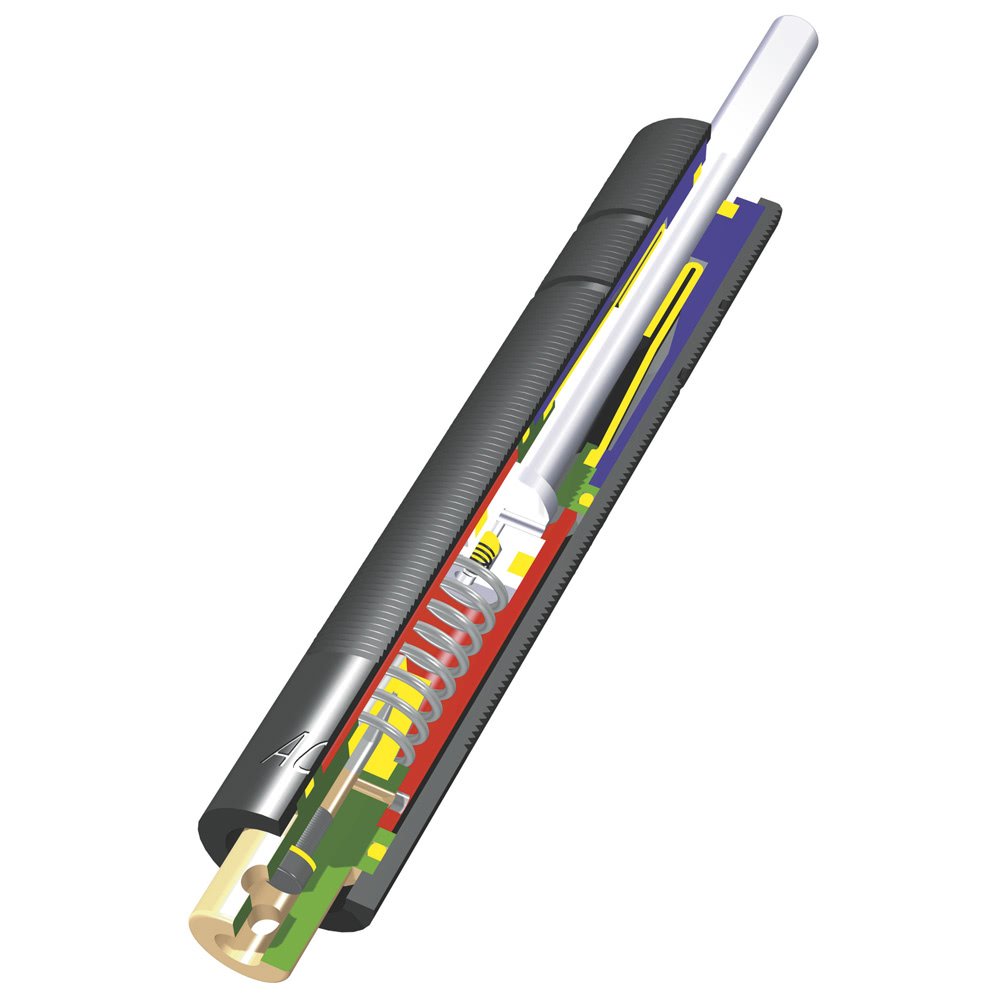

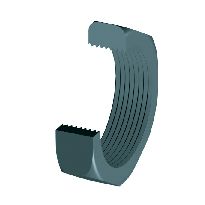

ACE's PMCN150, PMCN225, and PMCN600 family of shock absorbers are distinguished by a compact, perfectly sealed cap. This protective bellows made of TPU (thermoplastic polyurethane) securely envelops ACE's proven rolling diaphragm to protect it from the outside environment. This type of equipment does not allow any infiltration of cutting agents, lubricants or cleaners. The operation of this damper is then preserved, and remains ready for installation and maintenance-free. They are also available entirely in stainless steel.

Without access to compressed air, the PMCN range represents an alternative solution to the pressure scraper type SP. Reliable protection against aggressive media, these miniature dampers are the ideal product for all applications where standard dampers require maintenance too quickly, for example, in machining centres or other mechanical engineering applications.

Capacity: 20 Nm/Cycle to 136 Nm/Cycle

Impact speed: 0.06 m/s to 6 m/s. (other speeds on request)

Operating temperature : 0 °C to 66 °C

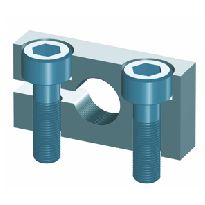

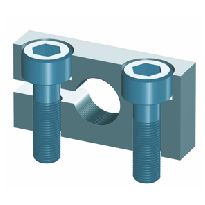

Mounting: your choice

Fixed stop: integrated

Materials: Outer body: corrosion-resistant coated steel; guide bush: plastic; piston rod: hardened stainless steel (1.4125, AISI 440C); cap: TPU, insert: stainless steel (1.4404/1.4571, AISI 316L/316Ti); rolling diaphragm: EPDM

Damping fluid: oil, temperature stable

Scope of application: manufacturing and processing centres, clean room areas, pharmaceutical technology, medical technology, food industry, linear slides, pneumatic cylinders, machines and systems

Note: The final pre-test must be carried out on the application.

Safety instructions: Do not paint the shock absorbers due to heat emission.

Special accessories available on request

Manufacturing and machining centres, clean room area, pharmaceutical technology, medical technology, food industry, linear slides, pneumatic cylinders, machines and plants.

Increases production rate

Prolongs machine life

Reduces construction costs

Reduces maintenance and noise

-

View accessories

-

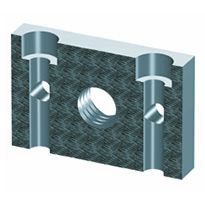

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories