SC190 to 925 series

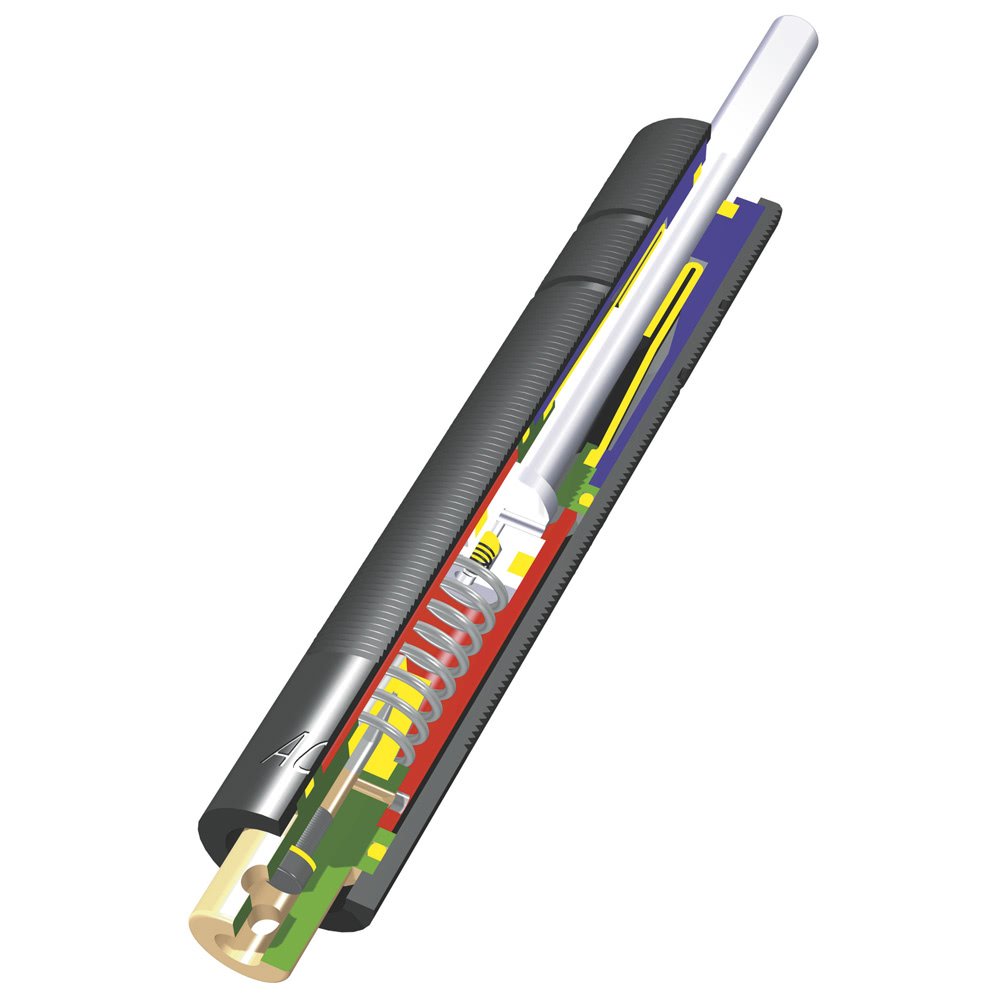

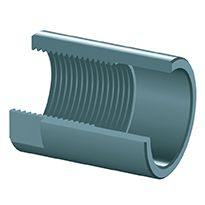

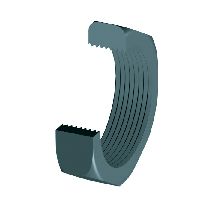

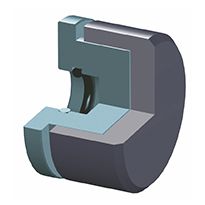

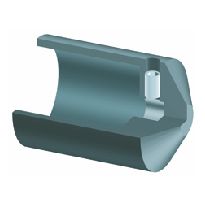

Ideal for soft damping: the letters "SC" in the model code of the ACE product family SC190, SC300, SC650 and SC925 stand for "soft contact". These one-piece miniature shock absorbers are designed so that they can be configured with a linear or progressive braking curve. Soft damping is a characteristic achieved by long, special strokes producing smooth deceleration and low reaction forces.

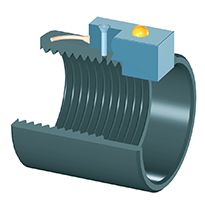

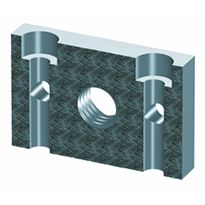

These maintenance-free, ready-to-install hydraulic elements are equipped with an integrated fixed stop. An adapter for radial forces allows angles of impact of up to 25° to be accepted. Thanks to the overlapping effective mass ranges, these shock absorbers cover an effective mass range from less than 1 kg to more than 2,000 kg!

The miniature shock absorbers of the product family SC190 to SC925 are used in mechanical engineering and mainly in the handling and automation sectors.

Capacity: 25 Nm/Cycle to 110 Nm/Cycle

Impact speed: 0.15 m/s to 3.66 m/s (other speeds on request)

Operating temperature : 0 °C to 66 °C

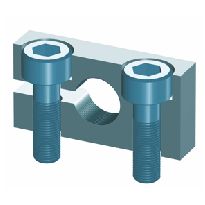

Mounting: your choice

Fixed stop: integrated

Materials: outer body, accessories: corrosion-resistant coated steel; piston rod: stainless steel, hardened and tempered.

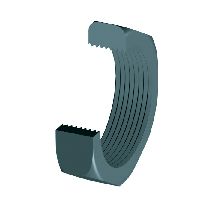

Damping fluid: oil, temperature stable

Note: For an accurate end position, use an external end stop.

Safety instructions: External materials in the immediate environment can attack the sealing components and shorten the service life. Please contact us for proposals for suitable solutions. Do not paint the

shock absorbers due to heat emission.

Nickel plated or Weartech (seawater resistant) finish or other special finishes available on special order. Models without rod bumper.

Linear slides, pneumatic cylinders, handling modules, machines and plants, manufacturing and machining centres, measuring tables, machine tools

Increases production rate

Prolongs machine life

Reduces construction costs

Reduces maintenance and noise

Les amortisseurs industriels ACE sont des appareils professionnels de décélération linéaire, pour les systèmes actuels d’automatisation sophistiquée.

Haute capacité et construction renforcée assurent une durée de vie importante dans des conditions sévères. Une vaste gamme de taille est disponible pour des masses de quelques grammes jusqu’à plusieurs centaines de tonnes.

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories