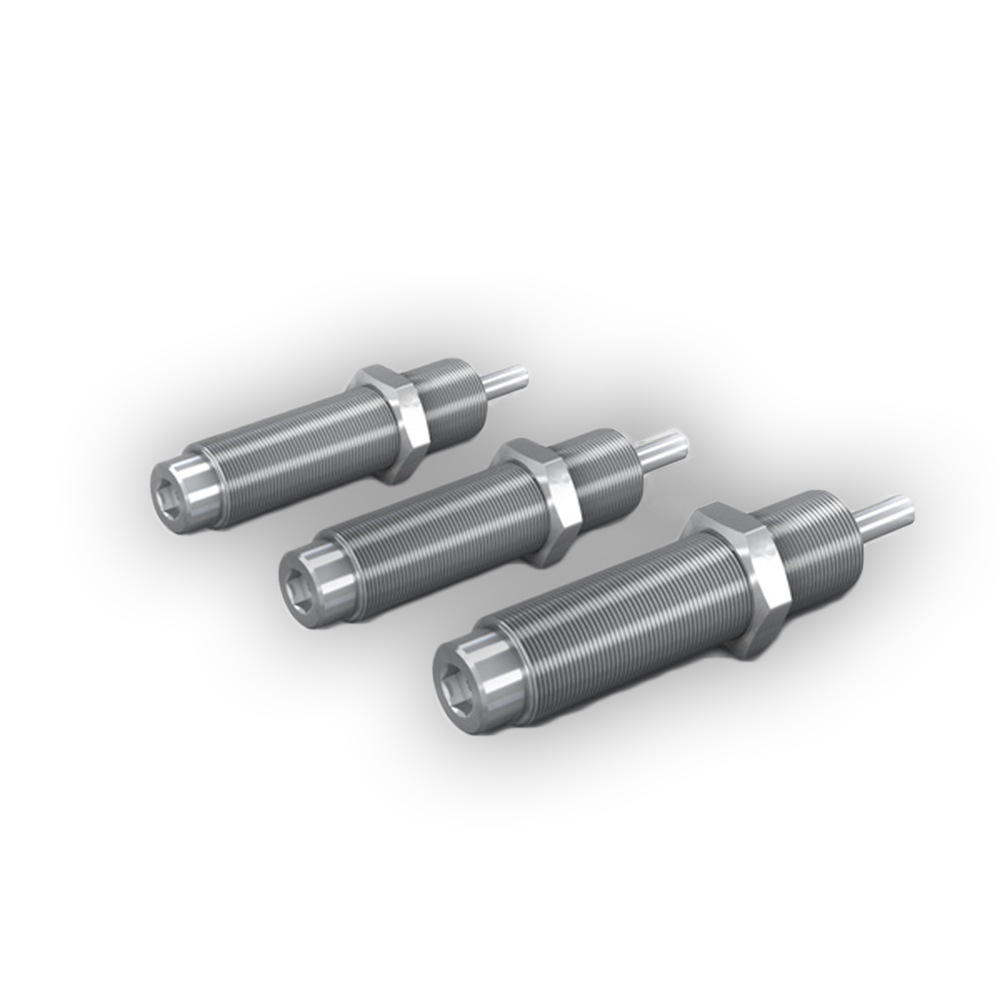

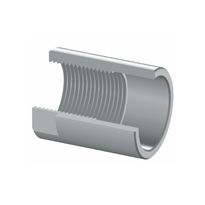

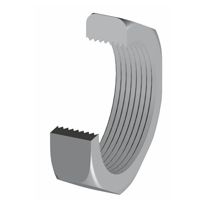

MC150 to 600-V4A series

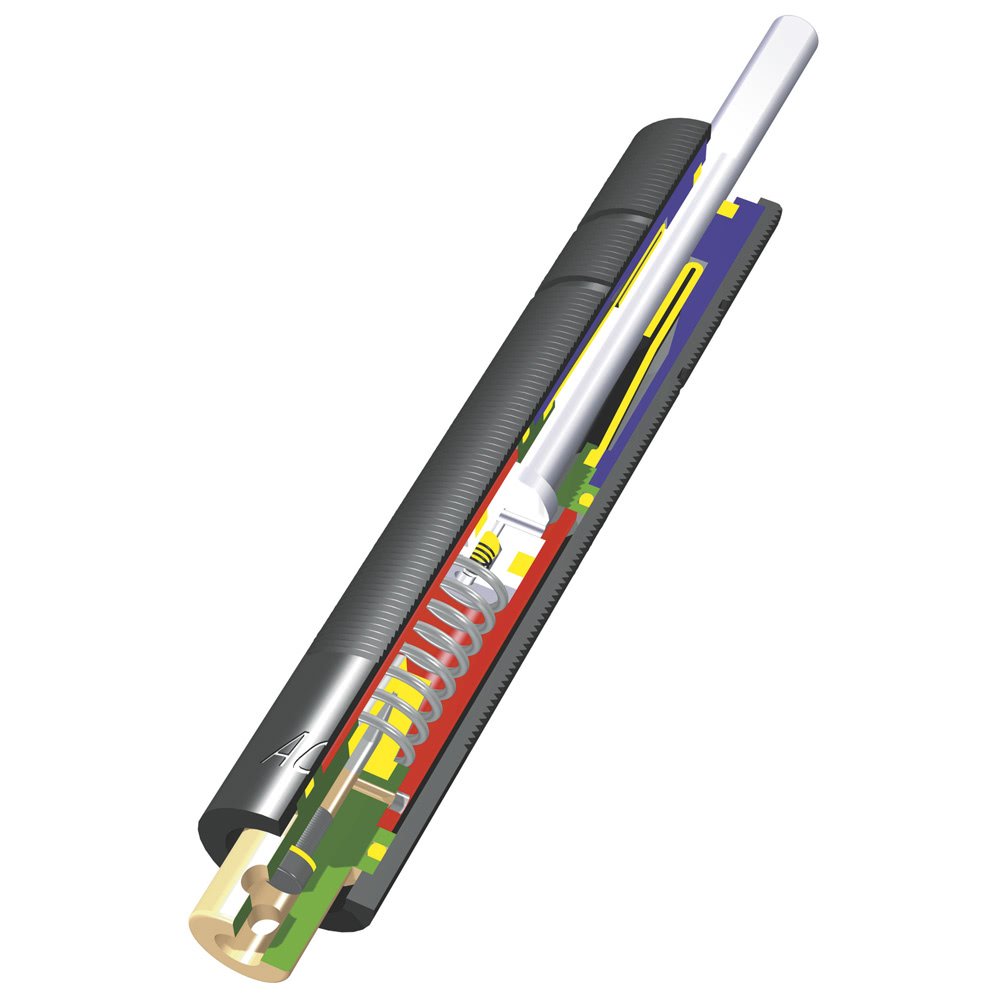

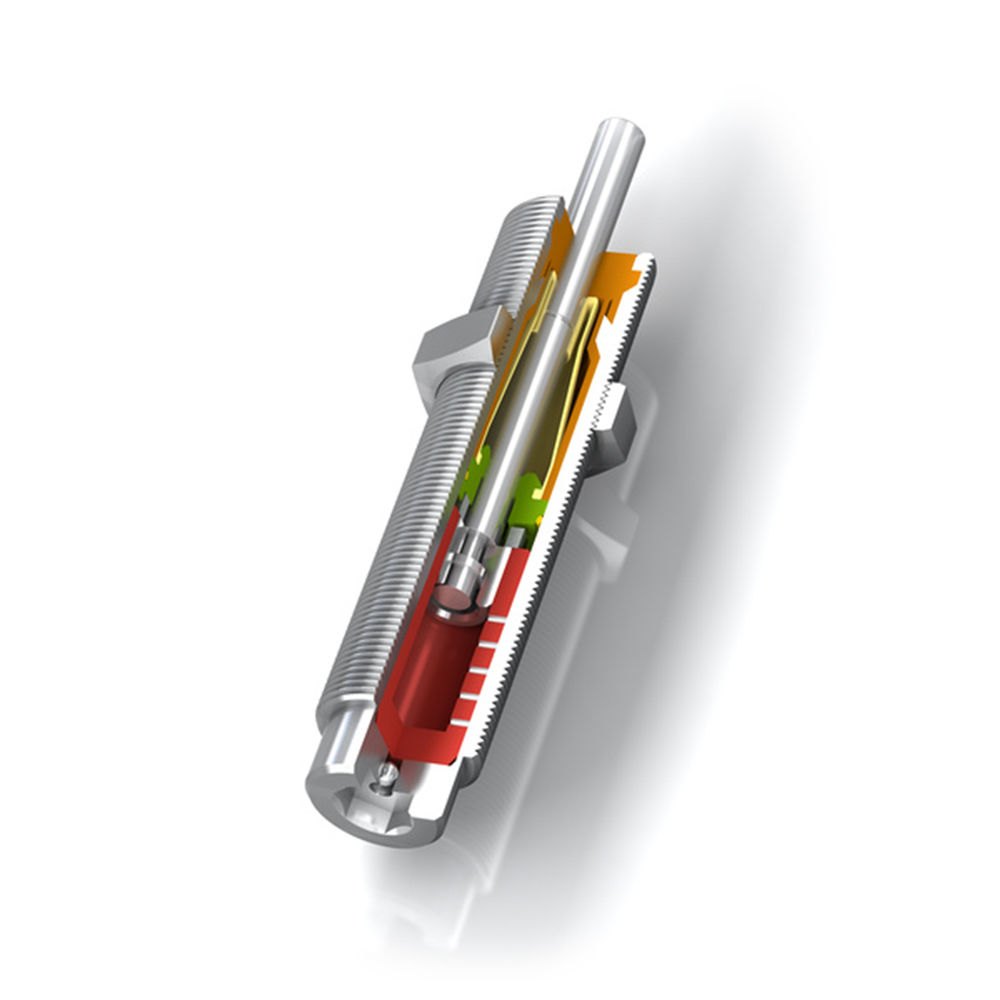

Exceptional in every respect: these high-performance miniature stainless steel shock absorbers are based on ACE's MC150, MC225 and MC600 product family and its proven damping technology. Thus, these special dampers offer all the advantages of standard MC units such as ACE's proven rolling diaphragm technology for maximum service life and direct installation in a pressure chamber of up to 7 bar.

Thanks to the perfectly progressive maximum energy absorption and the effective mass potential, their use is further optimized by the external housing and a comprehensive range of accessories made of stainless steel (material 1.4404).

Miniature shock absorbers made of stainless steel are mainly used in medical and electronic technology, but also in shipbuilding and the chemical and packaging industries as well as in the food industry, for which they are filled with a special oil (optional) in order to meet the approval requirements (NSF-H1) of this market.

Capacity: 20 Nm/Cycle to 136 Nm/Cycle

Impact speed: 0.06 m/s to 6 m/s (other speeds on request)

Operating temperature : 0 °C to 66 °C

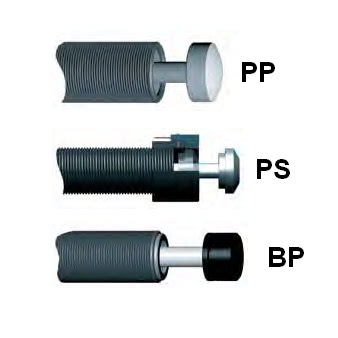

Mounting: your choice

Fixed stop: integrated

Materials: Outer body, nut, accessories: stainless steel (1.4404, AISI 316L); guide bush: plastic; piston rod: hardened stainless steel (1.4125, AISI 440C); rolling diaphragm : EPDM

Damping fluid: oil, temperature stable

Note: For an accurate end position, use an external end stop.

Safety instructions: External materials in the immediate environment can attack the rolling seal and shorten its life. Please contact us for proposals for suitable solutions.

Can be used in pressure chambers up to 7 bar.

On request: Special oil with food approval. Special threads or other special options available on request.

Cleanroom area, pharmaceutical technology, medical technology, food industry, linear slides, pneumatic cylinders, handling modules, machines and plants, manufacturing and processing centres, measuring tables

Increases production rate

Prolongs machine life

Reduces construction costs

Reduces maintenance and noise

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories