MC64-V4A series

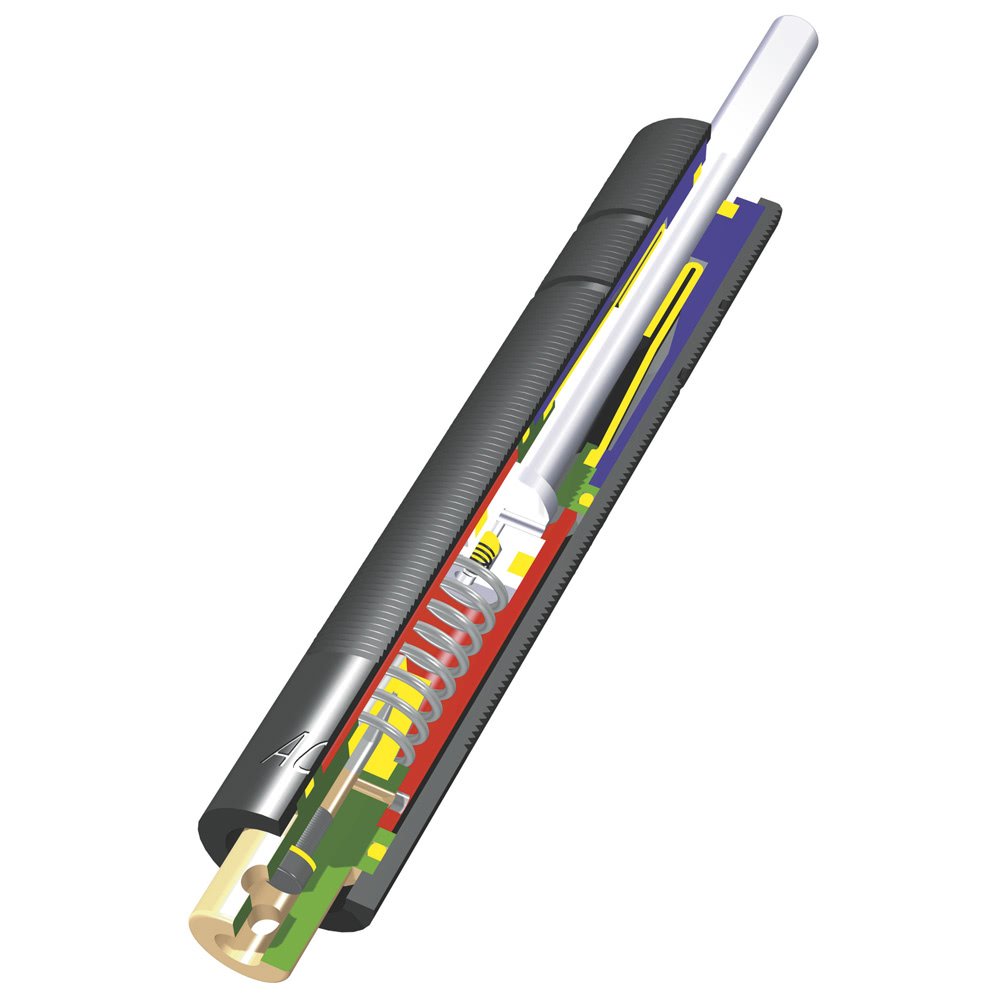

The latest shock absorber technology in stainless steel: The MC6450 and MC64100 self-compensating industrial shock absorbers of the tried and tested ACE MAGNUM range are also available with all external components in stainless steel, material 1.4404 (except piston rod). They are filled at the factory with a special oil, which meets the approval requirements (NSF-H1) of the food industry. Like the standard product family, the MAGNUM stainless steel models are characterised by their robust and modern sealing technology, high energy absorption in a compact design, integrated fixed stop and high damping capacity. Equipped with a PU head, they are available with threads from M33x1.5 to M64x2 for strokes up to 100 mm. These self-compensated stainless steel industrial shock absorbers from ACE are mainly used in the food, medical, electronics and offshore industries, but also in many other sectors.

Capacity: 170 Nm/Cycle to 3,730 Nm/Cycle

Impact speed: 0.15 m/s to 5 m/s. Other speeds on request.

Operating temperature: -12 °C to +66 °C. Please consult us for different temperatures.

Mounting: optional

Fixed stop: integrated

Materials: Outer body, guide bush, accessories, nut: stainless steel (1.4404, AISI 316L); piston rod: hard chromed steel; stop: stainless steel (1.4404, AISI 316L) with elastomer insert; return spring: stainless steel

Damping fluid: NSF-H1 certified special oil

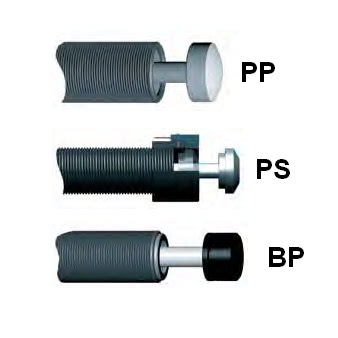

Note: Noise reduction bumper (PP) included. For emergency stop applications and for continuous operation (with additional cooling) it is sometimes possible to exceed the specified maximum capacities. In this case, please consult us.

Safety instructions: External materials from the immediate environment can attack the sealing components and shorten the service life. Please contact us for proposals for suitable solutions. Do not paint the shock absorbers due to heat emission.

Special oils, other special options and special accessories are available on request.

Translated with www.DeepL.com/Translator (free version)

linear carriages, rotary units, turntables, food industry, medical technology, gates, machines and plants, machine tools, machining centres, Z-axes

Increases production rate

Prolongs machine life

Reduces construction costs

Reduces maintenance and noise

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories