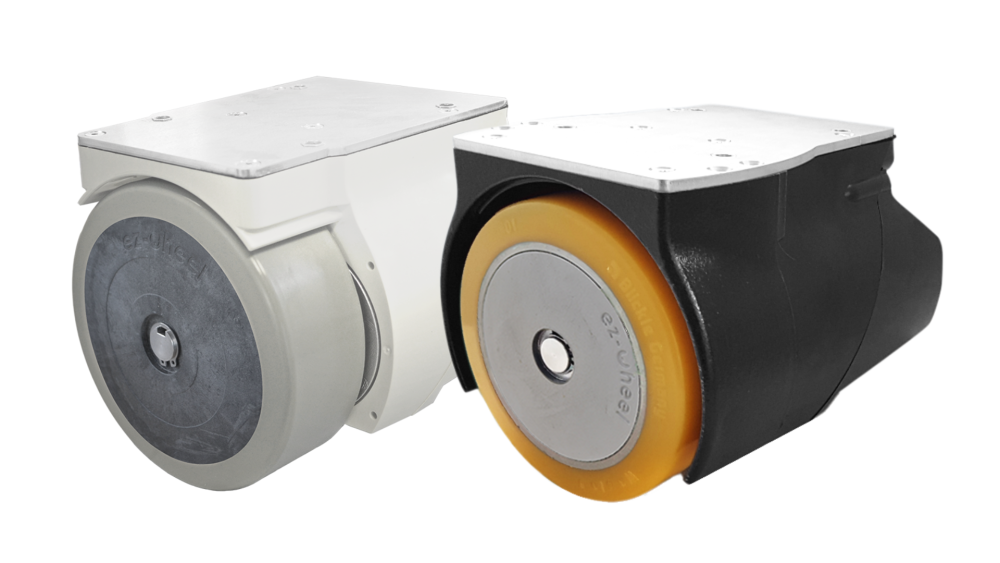

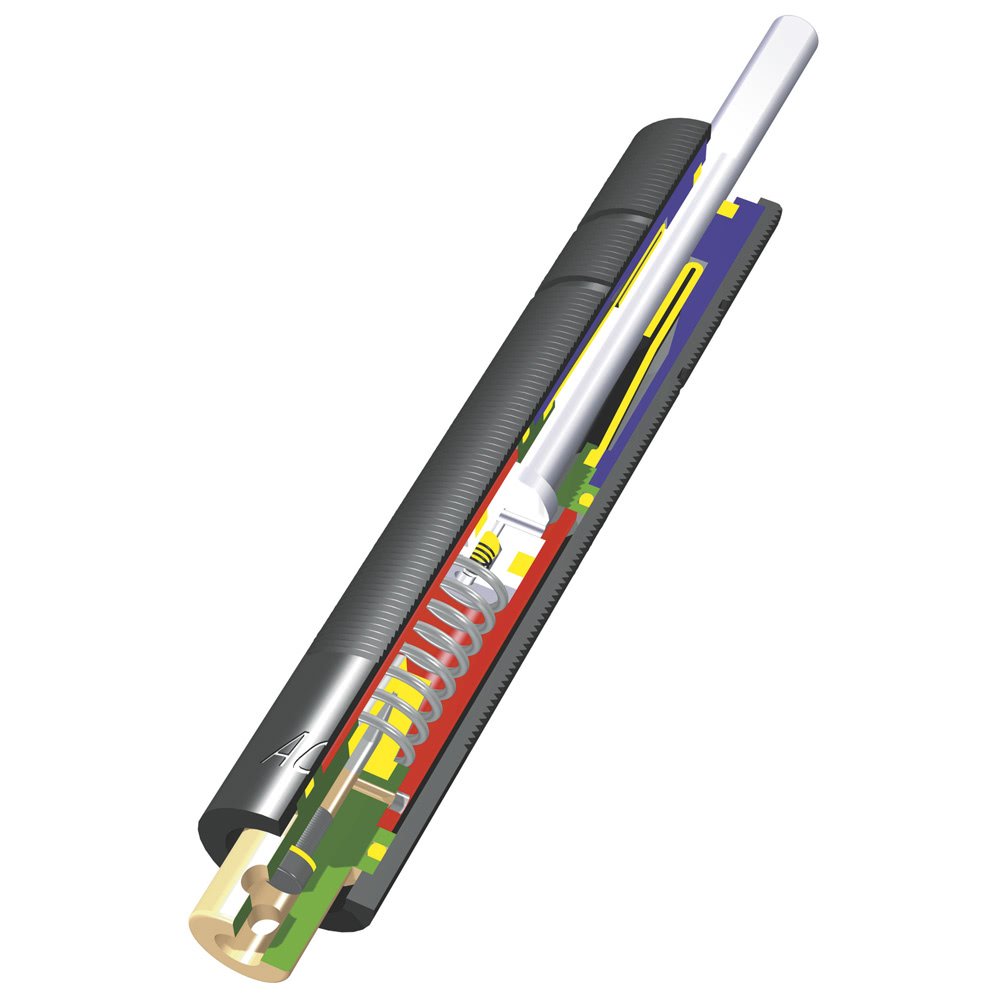

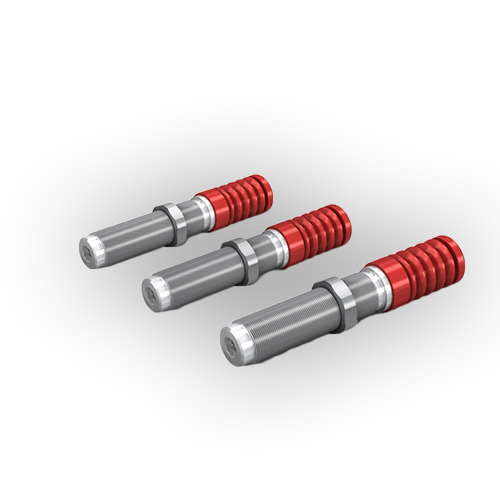

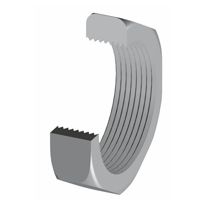

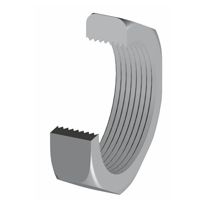

PMCN150 to 600-V4A series

Hermetically sealed and rustproof: ACE's PMCN150, PMCN225 and PMCN600 family of shock absorbers is also available in stainless steel, which is of great interest in the food and packaging industries. The main distinguishing feature is the compact, completely sealed bellows between the tube and the cap, made of TPU (thermoplastic polyurethane). This protection safely envelops the ACE rolling diaphragm to protect it from the outside environment, leaving no chance for aggressive fluids to penetrate.

The PMCN range is an excellent alternative if the type SP pressure wiper option cannot be used due to the unavailability of compressed air. The miniature dampers in the PMCN range, made of stainless steel, are intended primarily for use in the food industry, but can also be an interesting alternative in sectors where an elegant appearance is required, such as shipbuilding.

Capacity: 20 Nm/Cycle to 136 Nm/Cycle

Impact speed: 0.06 m/s to 6 m/s. Other speeds on request.

Operating temperature : 0 °C to 66 °C

Mounting: your choice

Fixed stop: integrated

Materials: Outer body: stainless steel (1.4404, AISI 316L); guide bush: plastic; piston rod: hardened stainless steel (1.4125, AISI 440C); cap: TPU, insert steel: stainless steel (1.4404/1.4571, AISI 316L/316Ti); rolling diaphragm: EPDM

Damping fluid: oil, temperature stable

Note: The final pre-test must be carried out on the application.

Safety instructions: Do not paint the shock absorbers due to heat emission.

Special accessories available on request

manufacturing and machining centres, clean room area, pharmaceutical technology, medical technology, food industry, machines and plants

Increases production rate

Prolongs machine life

Reduces construction costs

Reduces maintenance and noise

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories

-

View accessories