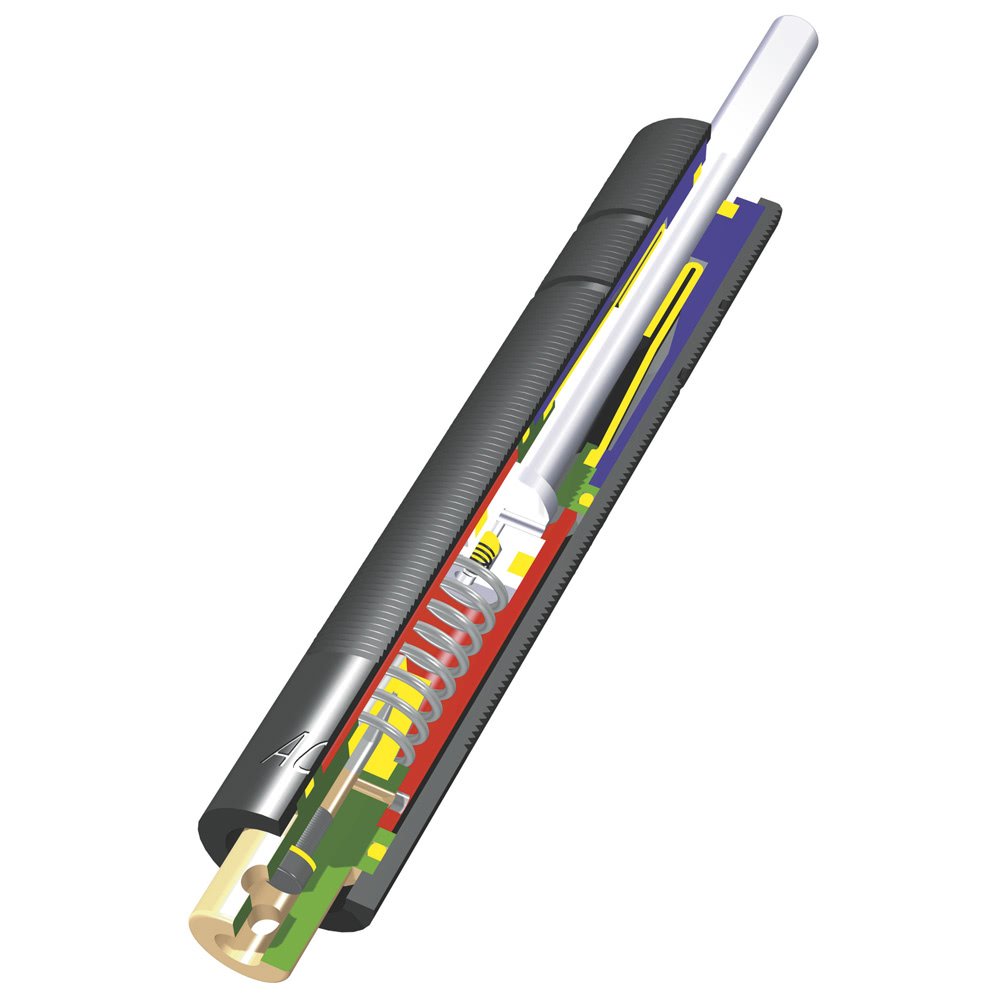

Float Switch

Industrial float switches are simple yet effective devices used to detect and control liquid levels in various industrial applications. They operate on a basic principle: a buoyant float rises or falls with the liquid level, triggering a switch that activates or deactivates a control circuit.

Types of Industrial Float Switches:

Stainless Steel Float Switches: These are highly durable and resistant to corrosion, making them ideal for harsh environments and aggressive chemicals.

Plastic Float Switches: These are lightweight and cost-effective, suitable for less demanding applications and non-corrosive liquids.

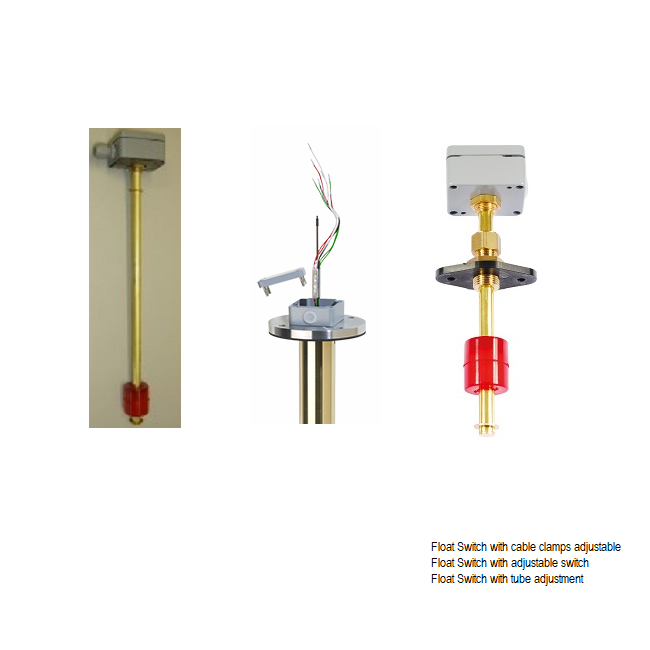

Brass Float Switches: These offer a good balance of durability and affordability, suitable for a wide range of industrial applications.

Adjustable Float Switches: These allow for precise level setting by adjusting the float's position, providing flexibility in various applications.

Mini Float Switches: These compact switches are ideal for space-constrained applications and can be easily integrated into tight spaces.

Applications:

- Pump Control: Preventing pumps from running dry or overflowing tanks.

- Alarm Systems: Triggering alarms for high or low liquid levels.

- Fluid Level Monitoring: Monitoring levels in tanks, reservoirs, and other containers.

- Process Control: Controlling valves, motors, and other equipment based on liquid levels.

Advantages:

- Simple and Reliable: Easy to install and maintain, with minimal maintenance requirements.

- Cost-Effective: Affordable compared to other level sensing technologies.

- Durable and Long-lasting: Designed for harsh industrial environments.

- Versatile: Suitable for a wide range of liquids and applications.

By effectively monitoring and controlling liquid levels, industrial float switches play a crucial role in ensuring efficient and safe operations across various industries.