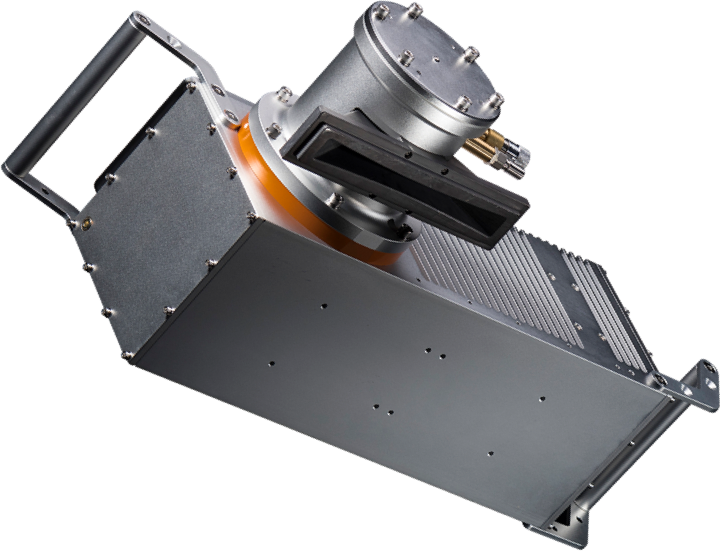

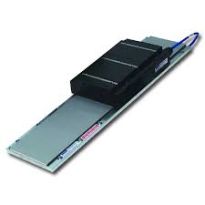

Direct Drive

Kollmorgen pioneered the development of direct drive technology, and today offers the broadest range of direct-drive motors in the industry. Direct drive motors offer industry-leading performance, zero maintenance, clean mechanical assembly, improved accuracy, higher throughput, better reliability, and smooth, quiet operation to suit a wide variety of machine design needs.

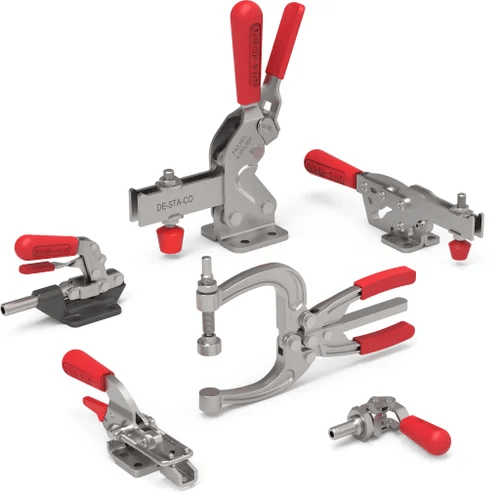

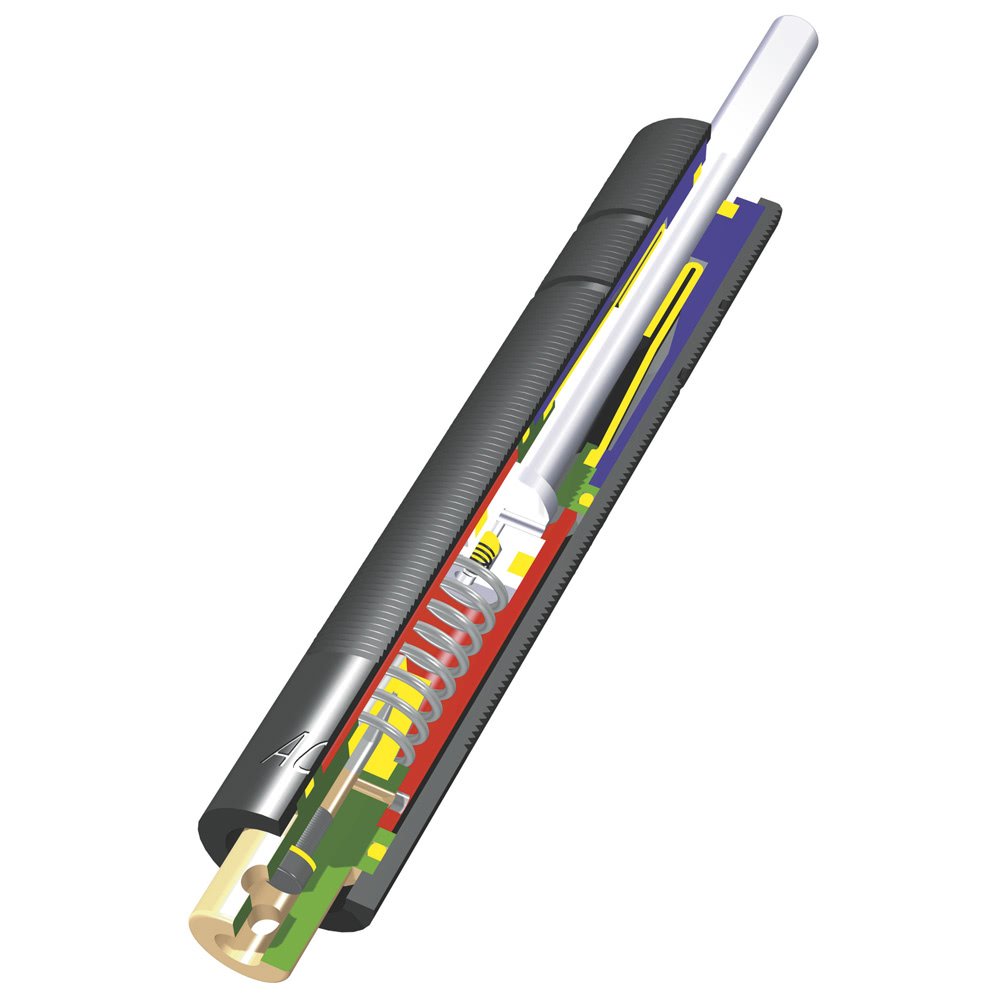

Mechanical transmission, such as gearboxes, timing belts, pulleys or lead screws, introduce backlash, mechanical losses and objectionable audible noise that can reduce machine performance, increase machine size and weight.

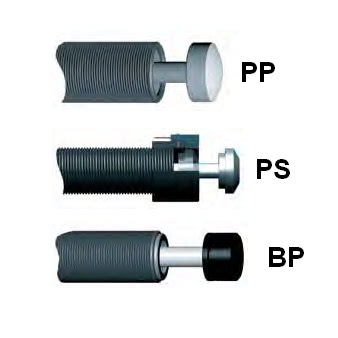

Direct Drive motors, either housed rotary (DDR), cartridge rotary (CDDR) or frameless (KBM high-voltage rotary or TBM low-voltage rotary or DDL linear motors) directly mount to the load to be driven thereby eliminating the transmission, providing a much more robust alternative (Want to know more about frameless motors or direct drive linear technology? View our What is a Frameless Motor? page or How Does a Direct Drive Linear Actuator Work? blog post). System maintenance is greatly reduced as mechanical parts prone to wear are removed, dramatically improving MTBF. Also improved are load acceleration, lower power consumption, reduced system inertia, and higher precision are major advantages that direct drive solutions can provide.