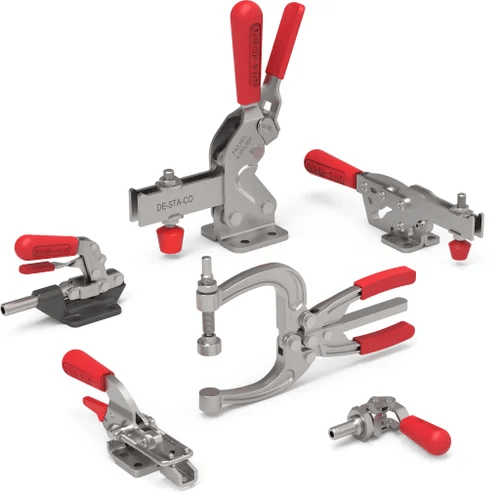

Workholding

Erwin Halder KG is a manufacturer of products designed for clamping workpieces. The product selection offering these "gripping solutions" is categorized into

- Modular fixture systems

- T-slot systems (V40, V70, V70eco)

- Hole and dowel systems (L12, L16)

- Combo parts

- Standard parts for fixture systems

- Multiple clamping systems

- Multi-vices (MS 125, MS 125eco)

- Zero-point clamping systems

- Basic elements

All these standardised products are available from stock.

We also make the CAD data associated with all components available for download in various formats.

Your contacts at our company will be happy to help you find the clamping solution that is right for you. Apart from visits to your premises with our product display vehicle, which is equipped with products from our entire selection, we also offer classes at your training centre, where you can learn everything there is to know about our latest workpiece clamping technology.

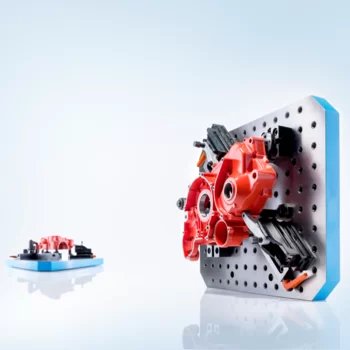

MODULAR FIXTURE SYSTEMS - THE RIGHT SYSTEM FOR EVERY PURPOSE

Two systems that are effortlessly interchangeable allow you to perfectly adapt the fixture to the specific requirements at hand. The systems can be selected based on workpiece and production process and offer maximum flexibility thanks to their modular design.

T-slot systems

Tempered base plates are fitted with a T-slot system.

This feature makes it possible to fix system components in place and clamp them at the same time. A particularly good choice for machining complex workpieces.

Hole and dowel systems

The base plates with hole and dowel system allow operators to quickly set up and precisely machine workpieces with simple geometries. Hole and dowel systems can reach the same level of flexibility achieved by the T-slot system thanks to mounted combo parts.