Zero-Point Clamping Systems

The quick-change system for reduced set-up times.

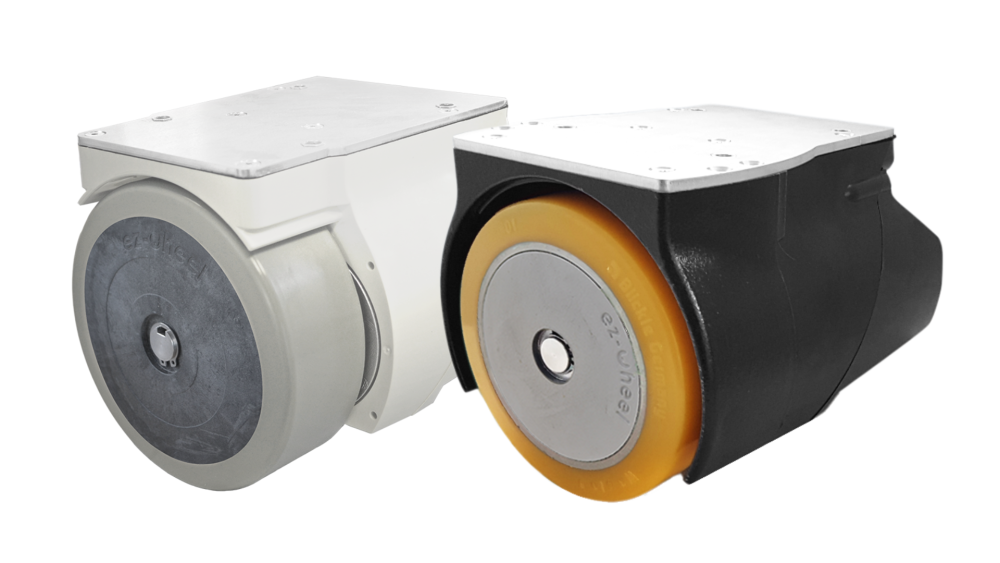

Coupling elements for the simultaneous clamping and centering of fixture elements, designed as quick-change systems for reduced set-up times.

- Referenced clamping of fixture elements thanks to positioning at the "zero point" with perfect repeatability.

- Allows for the machining of workpieces in several work steps on different machines.

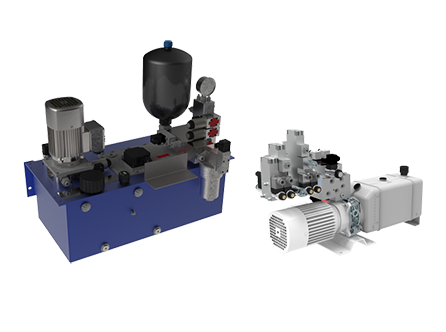

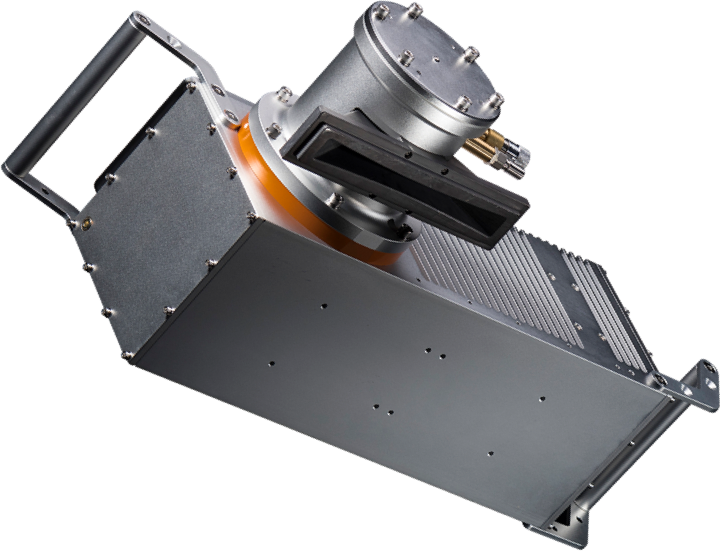

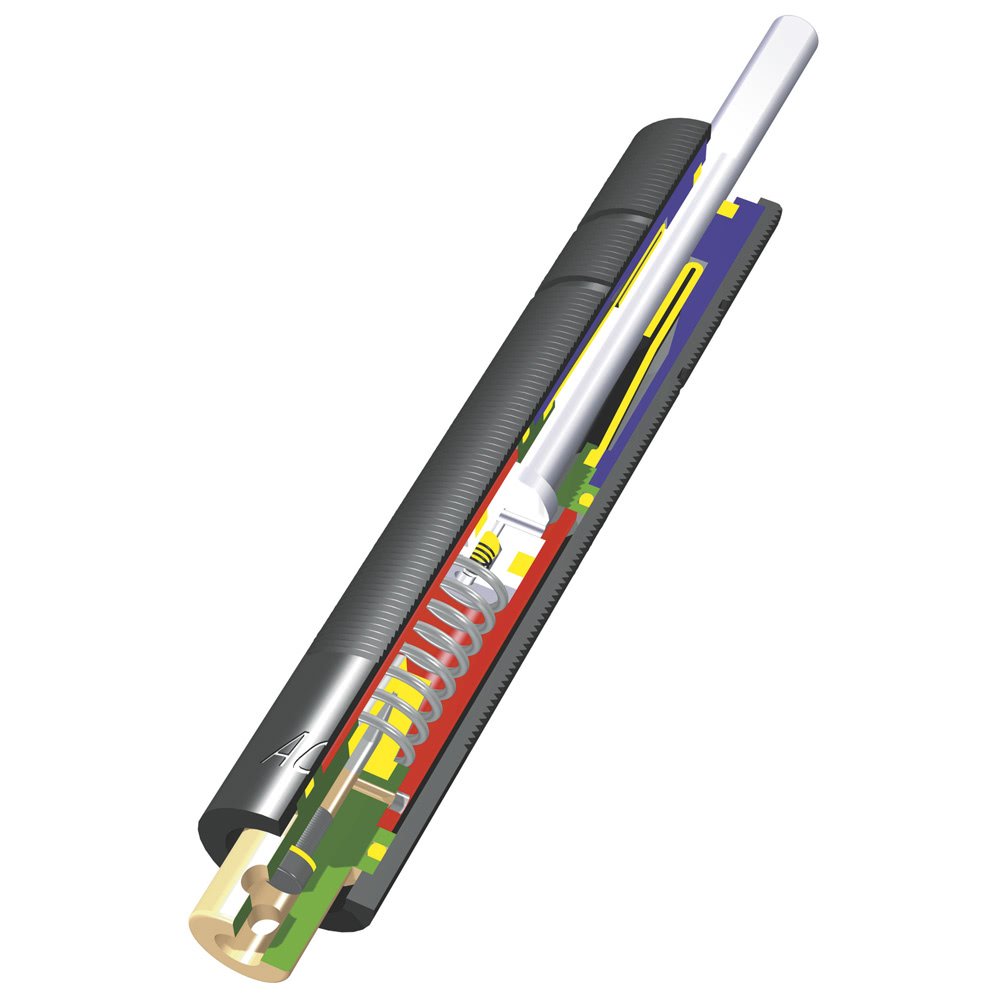

Aside from the highest flexibility offered by our zero-point clamping systems - whether actuated hydraulically, as an installation version with integrated lifting of the fixtures or sporting a modular design, this technology ensures an outstanding level of product reliability, long-lasting accuracy and a reference point that will remain clean thanks to the bottom-to-top design of the base element and the connecting ring integrated at the fixture.

Features:

- Up to 30 kN of retention force.

- Mechanical, pneumatic and hydraulic actuation.

- With anti-turn locking device when used with individual elements.

- Superior efficiency, repeatability and cost savings.

- Suitable for use on all machines.

- Can also be integrated into Halder fixture systems.

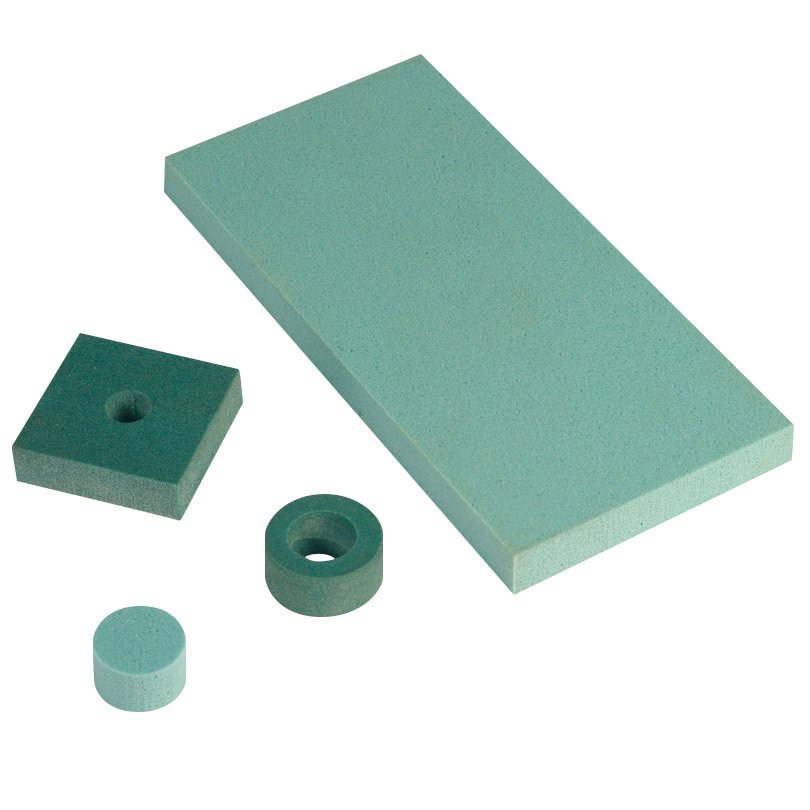

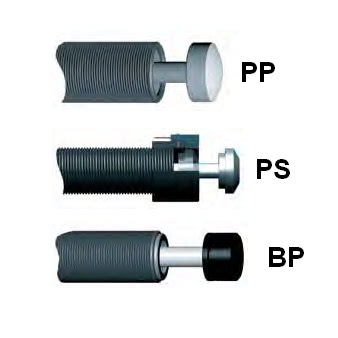

The range of zero-point clamping systems included in our workholding systems selection encompasses such product groups as connecting elements, connecting rings, base plates, supporting plates, coverings and pressure amplifiers. These system parts are available from stock.

The selection is divided into the categories of

- Connecting elements / connecting rings

- Base plates / supporting plates

- Accessories for zero-point clamping systems